Vibracoustic optimises bundling of thermal car components

Vibracoustic has designed, developed and tested its innovative Thermal Management Decoupling System, which supports and isolates the co-located thermal technologies commonly used in next-generation battery electric vehicles (EVs).

The system optimises the bundling of thermal components, such as heating, ventilation and air-conditioning to save space, increase efficiency and streamline assembly. This all-in architecture can be easily carried over into other vehicles without additional engineering.

To date, the packaging of thermal systems in EVs has proven challenging for OEMs looking to maximise space. By co-locating or bundling thermal systems, rather than separating them throughout a vehicle, OEMs and Tier 1 suppliers can save space while also simplifying routing complexity, and hose and cable lengths. This reduces pressure losses between thermal components, and improves system performance and efficiency. It also results in much easier, streamlined assembly and service access.

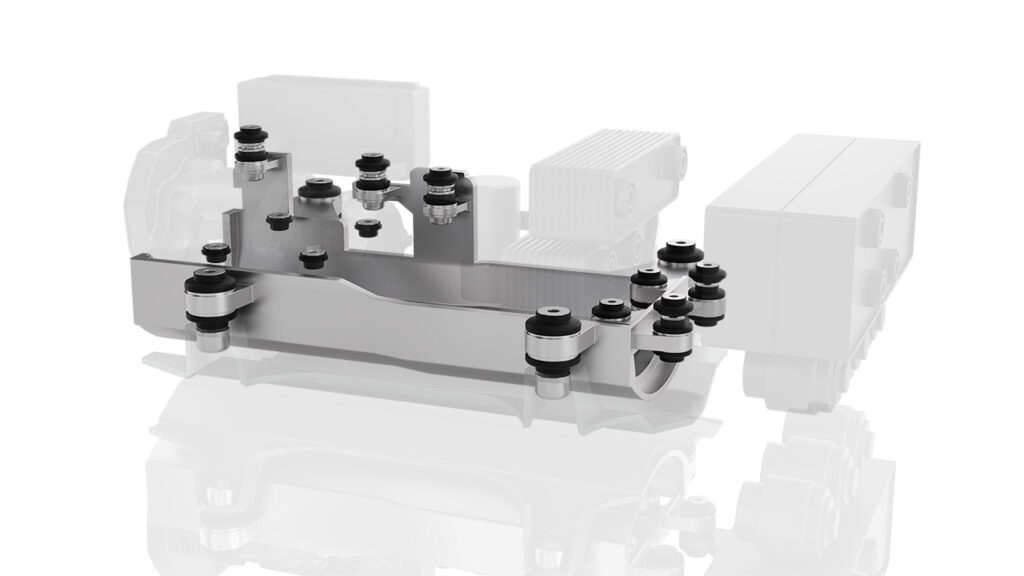

Vibracoustic’s Thermal Management Decoupling System has been adopted by leading international OEMs for next-generation, large EVs, such as SUVs, pick-ups and vans. The bundled thermal module consists of an air-conditioning compressor, accumulator, pumps and heat exchanger, among other components, mounted directly on the vehicle chassis, and connected by hoses and cables.

Dr Jörg Böcking, CTO at Vibracoustic, said: “This project was an important opportunity for us to elevate NVH [noise, vibration and harshness] management in next-generation battery electric vehicles.

“Our team developed a bracket and mounting system that effectively cradles and isolates the consolidated systems, improving vehicle refinement.”

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS