Temperature-responsive material performs well against thermal runaway

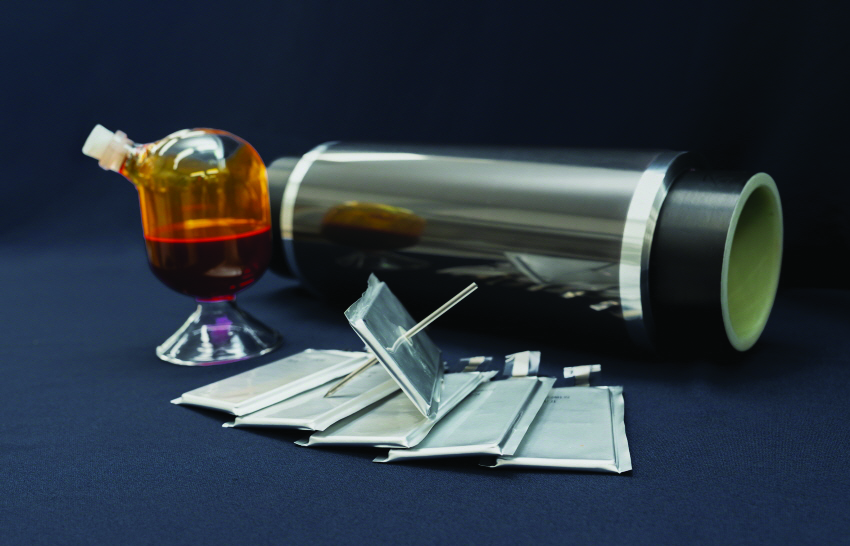

(Image courtesy of LG Chem)

LG Chem has developed a temperature-responsive material that can suppress thermal runaway and be manufactured in a high-volume, roll-to-roll process, writes Nick Flaherty.

The Safety Reinforced Layer (SRL) is a composite that can be as thin as 1 μm. It is placed inside a battery cell between the cathode layer and the current collector, with the aluminium foil acting as the electron pathway.

Thermal runaway is a leading cause of EV battery fires, and it occurs when the cathode and anode inside the battery unintentionally come into direct contact, causing a short circuit and generating heat. Within seconds, the temperature can rise to nearly 1000 C, leading to a fire.

Made from molecularly engineered polythiophene (PTh) and carbon additives, the SRL interrupts current flow during voltage drops or overheating without harming battery performance.

The material has been designed to be highly responsive, with its electrical resistance increasing by 5000 ohms (Ω) for every 1 C rise in temperature. It is expected to be effective in preventing fires by quickly blocking the reaction path at the early stages of overheating.

In battery impact and penetration tests, the batteries equipped with the SRL either did not catch fire at all or extinguished the flames shortly after they appeared, preventing thermal runaway.

“This is a tangible research breakthrough that can be applied to mass production in a short period,” said Lee Jong-gu, CTO at LG Chem.

The SRL’s maximum resistance is over 1000 times higher than at normal temperatures, and it features reversibility, meaning resistance decreases and returns to its original state, allowing the current to flow normally again once the temperature drops.

When the battery temperature rises above the normal 90-130 C range, the SRL reacts to the heat, altering its molecular structure and suppressing current flow. This acts as a fuse to block the reaction path at the early stages of overheating.

The roll-to-roll process can produce 5 km of material daily on a 1700 mm roll.

The side chains of conductive polymers within the SRL have been tailored to trigger the transition at around 100 C, while ensuring the polymer’s high solubility in a commercially viable solvent, toluene, as opposed to chloroform.

The researchers found that including carbon additives in the SRL maintains its high conductivity under standard battery operation. Despite constituting <0.5% of the total cathode weight, thus preserving battery power and energy density, the SRL efficiently interrupts current flow when a short circuit occurs.

Safety verification on 3.4 Ah pouch cells, carried out in partnership with LG Energy Solution, showed a reduction in battery explosions from 63% to 10%.

In a penetration test involving mobile lithium cobalt oxide (LCO) batteries, where a nail was used to puncture them, only 16% of the regular batteries did not catch fire, but none of those with SRL did.

In an impact test on nickel cobalt manganese (NCM) batteries, where a 10 kg weight was dropped on them, all of the standard ones caught fire.

In contrast, 70% of the SRL batteries did not ignite at all, while the remaining 30% experienced flames but were extinguished within seconds.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS