Tackling EV tyre particulates

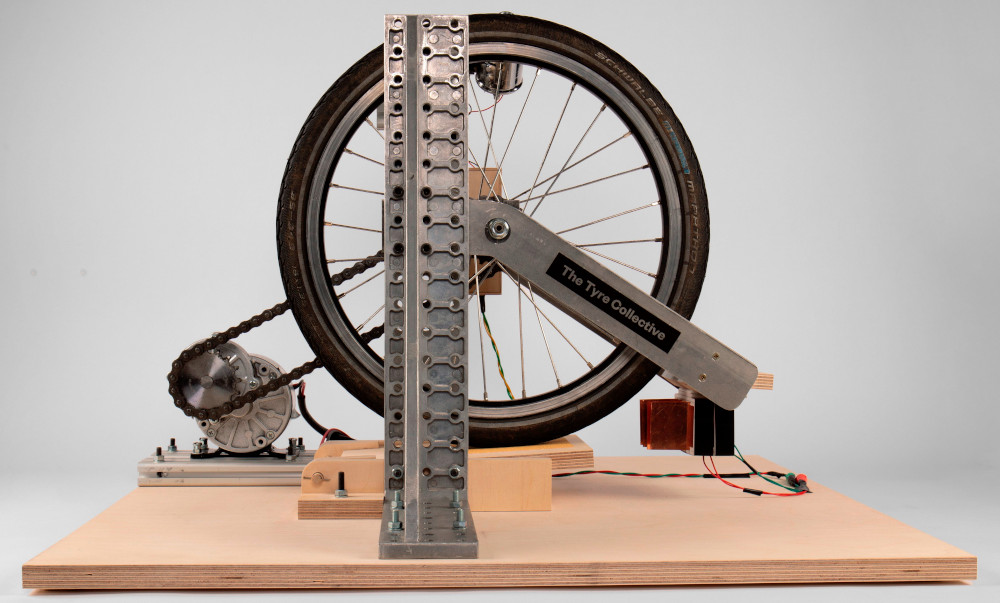

(Images courtesy of The Tyre Collective)

The most supportable claim by EVs to environmental friendliness is that they lead to cleaner air in towns and cities because they emit no combustion products (writes Peter Donaldson). The fly in that ointment is particles from tyre wear, of which EVs tend to generate more because they are heavier than comparable IC-engined vehicles and because many drivers are tempted to exploit their excellent acceleration with lead-footed enthusiasm.

The Tyre Collective is therefore working on a means of mitigating this problem at its source, by using a wheel-well-mounted device that uses a combination of electrostatics and aerodynamics to collect the particulate matter and store it for later disposal.

“The shape of our device controls the airflow, and then within that we use electrostatics to pull the particles out of the air, while everything that we don’t want to collect goes through,” explains co-founder and chief scientific officer Siobhan Anderson.

Electrostatics is the branch of physics that deals with static and slow-moving electric charges that build up on the surface of non-conducting materials through contact with other surfaces. The charges can have attraction and repulsion effects.

It is the carbon in the rubber that takes a static electric charge as wear particles are torn off the tyre, and the collection device is positioned low in the wheel arch behind the tyre, spanning its width. That position, says the company, enables the collector to take advantage of the airflow around the spinning wheel and, in tests on a rig, it has been shown to capture 60% of the airborne particles.

The particles in question fall into the PM2.5 category, meaning particulate matter with a diameter of less than 2.5 µm, which pose high risks because they are small enough to pass through respiratory membranes.

As well as collecting the material for disposal, The Tyre Collective is analysing its composition.

“There are many different chemical components in tyre wear, some of which we are not really familiar with because the raw tyre tends to change composition under the heat and stress of use,” Anderson explains. “So the pollutants that are coming out of it can differ quite significantly from the original material.

“I specialise in looking at the samples specifically for research organisations to analyse it chemically, and also for size and other characteristics. So we are able to look at exactly what is what in the sample and where it comes from.”

The company is working on its second generation of prototypes with refined electrostatics, and is running its first set of vehicle trials on a van making deliveries around London. Its partner on this pilot project is Zhero, a logistics company that operates a fleet of electric vans and high-capacity cargo bicycles.

“We are targeting light goods vehicles at the moment, fleets that are operating in urban environments and have regular routes and maintenance schedules. We will then expand from there to other commercial fleets,” Anderson says.

The Tyre Collective is targeting these initial markets with retrofit options, but when the system is more mature it intends to work with vehicle OEMs to integrate them into passenger cars on the production line.

“Essentially, it would be a bit of tech in your car that you wouldn’t know was there, and when you went for your MOT [the UK’s annual mandatory roadworthiness test] they would change the system’s filter,” she adds.

ONLINE PARTNERS