Novus urban e-bike nears production

(Images courtesy of Novus)

With an initial price of around €30,000, the Novus e-bike is aimed at people who want to make a statement about their embrace of ‘green’ technology rather than those who simply need practical urban transport (writes Peter Donaldson).

However, the 30 kW, 400 Nm, 85 kg, all-composite two-wheeler, which was on display at the Battery Show in Stuttgart in late June, promises exciting performance and exhibits some innovative engineering. What began as a spare-time project in 2010 and yielded a first prototype in 2019 is now close to being ready for production.

“At the beginning of September, we are going to launch the series production version, which has only a few detail differences from the prototype and is available on pre-order; we will start production at the end of the year,” says Rene Renger, the company’s founder and CEO.

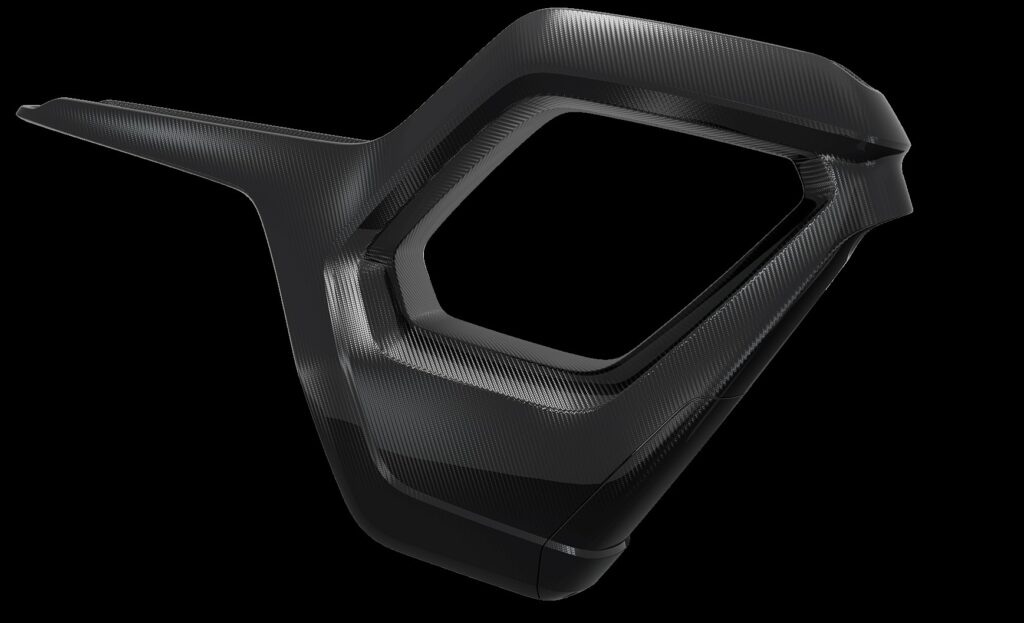

All the structural parts of the Novus are moulded from carbon fibre-reinforced plastic (CFRP), with the frame being a stressed-skin monocoque that also houses the battery, inverter and control electronics, providing protection from the elements. By itself, the frame weighs 6.9 kg, while the bike’s maximum load capacity weight is 125 kg.

The front fork and rear swing arm use the same type of construction, while the motor is integrated into the rear-wheel hub and the wheels are also CFRP, giving the whole bike a sleek, futuristic appearance while minimising weight.

“When we started, the first e-bikes had just come onto the market, but they all looked very old-fashioned,” Renger says. “At the same time, the first electrified motorcycle concepts looked as though somebody had just replaced the combustion engine with a big box – none of them seemed like the future of mobility.

“What we wanted though was to combine the lightweight feeling of an e-bike with the performance of a motorcycle in something that looks like it came out of a science fiction movie.”

The powertrain uses an innovative GKN transverse flux motor (TFM) inside the rear-wheel hub. In the motor, stator elements made from a soft magnetic composite material and C-shaped in cross-section are wrapped around the copper conductor ring, while the rotor with its own magnets spins outside the stator.

The TFM features a 3D magnetic flux design in which the flux moves axially through the stator, circumferentially through the rotor, and radially through the gap between them. Eliminating end windings, TFMs minimise copper losses, are well-suited to maximising the number of pole pairs and offer very high torque density.

The Novus is intended for urban riding, where its use of regenerative braking and its low weight should achieve a range of 130 to 150 km between charges from its 4.8 kWh battery pack, Renger says. He reckons that new battery developments over the next few years could increase the range to 200 or 250 km.

The battery pack itself contains 380 cylindrical 21700 cells and is housed in the bottom portion of the frame, with the inverter in the rear down-tube and the battery management system in the top tube. The battery is not intended to be removed routinely, but should last 50,000 km, when motor’s bearings might also need replacing.

The rear suspension uses a monoshock system typical of motorcycles, but the front fork is also a monoshock design like that on a bicycle, which Renger says is well-suited to light two-wheelers with relatively low top speeds – for the Novus, that is 130 kph.

There is a dedicated app for the Novus, which is fitted with a mount for a smartphone that can be used for navigation and remotely monitoring the bike’s functions and status, including its location. The phone can also act as the bike’s key.

The production version will also come with a bag that fits into the space in the centre of the frame, to provide space for a small amount of luggage and a charger.

ONLINE PARTNERS