Machine learning slices powertrain development phase

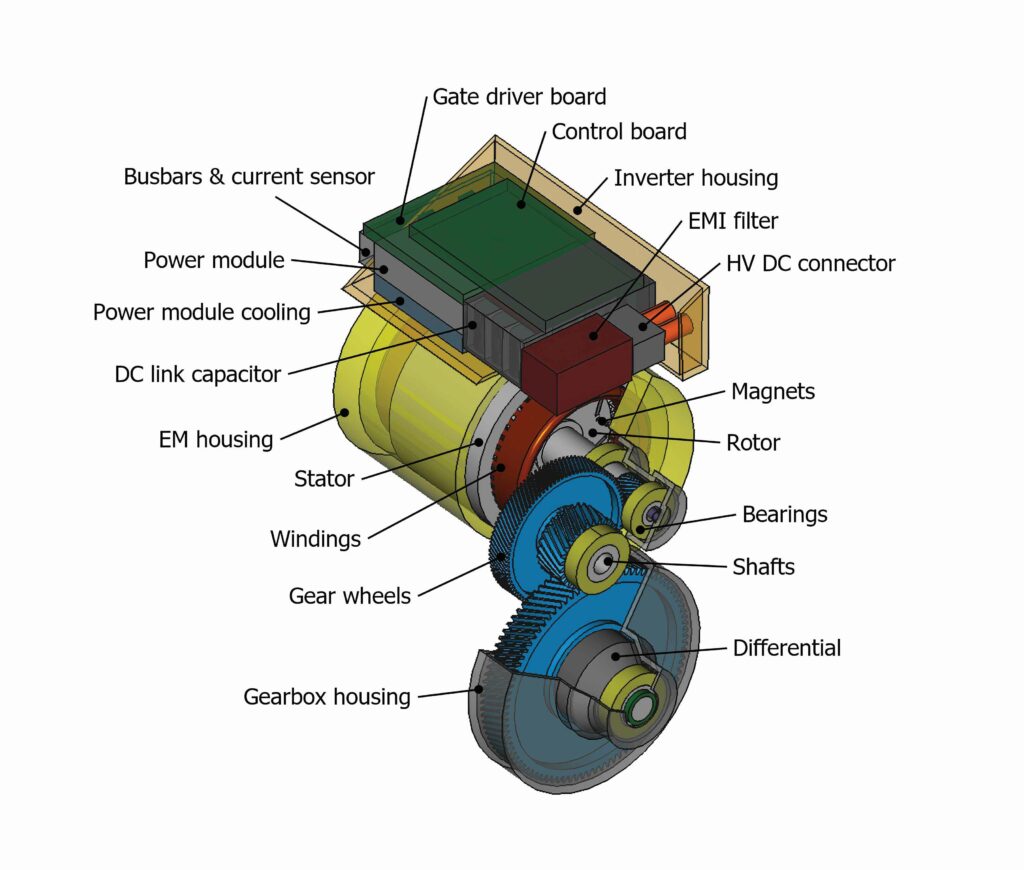

(Image courtesy of TU Graz)

Researchers at Graz University of Technology (TU Graz) have used machine learning to shorten the development phase of battery EV powertrains by several months, writes Nick Flaherty.

The 10-year Optimisation of Electric Drives (OPED) project combines simulation models of components with evolutionary optimisation algorithms, cutting development time to one day.

This technique optimises the entire powertrain design, from the power electronics to the electric machine through to the transmission in line with a set of constraints, similar to the evolutionary process in biology. The software is now being used by an Austrian automotive supplier.

The starting point for automatic optimisation is the input of the technical requirements for the constraints. These include power output, minimum service life, the maximum speed to be achieved and maximum space in the vehicle.

“Electric drives consist of a large number of components that can be designed very differently in order to fulfil the desired requirements,” says Martin Hofstetter, who led the project.

“If I make a small change to the electric machine it has an effect on the transmission and the power electronics, so it is extremely complex to make optimal decisions.”

An extra difficulty is there is no one perfect solution for a powertrain design as the priorities of manufacturers vary.

The software varies, combines about 50 design parameters simultaneously, and compares the simulated powertrains with manufacturers’ priorities. Bad variants are dropped, better ones optimised. After several hundred thousand calculations and simulation cycles, OPED finds ideal solutions and then selects from a manageable number of variants those it would like to develop.

The OPED system can be expanded with more criteria. The researchers have taken sustainability into account too.

The technique has also been extended to the development of an entire vehicle platform as part of a doctoral thesis by one of the researchers, Dominik Lechleitner. The aim is to save development and production costs.

“The OPED approach can be used for a wide variety of product developments, and we are happy to work with new industrial partners to adapt it to their challenges and goals,” says Hofstetter.

The technology has been spun-off by TU Graz as OPED Software.

ONLINE PARTNERS