Machine learning to reduce EV cost

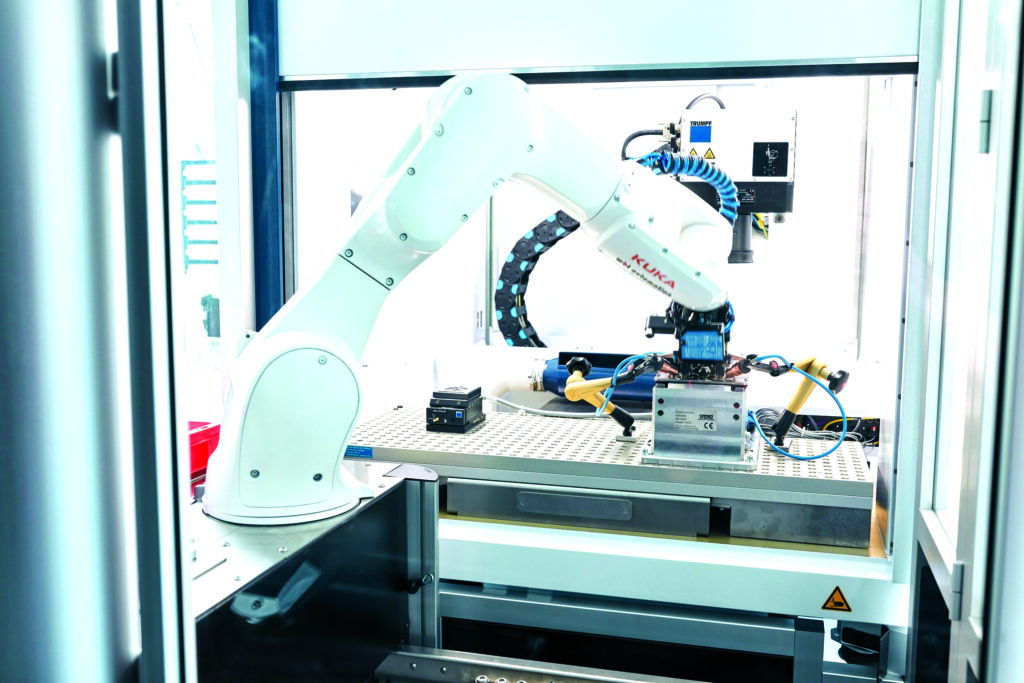

(Image courtesy of TRUMPF)

Machine learning is being used to improve the quality of laser welding systems and powder metal 3D additive manufacturing, writes Nick Flaherty. Laser welding machine maker TRUMPF is working with software developer SiMa.ai to develop lasers with artificial intelligence (AI). The goal is to equip several laser systems of TRUMPF with AI technology in the near future. This includes systems for welding, cutting and marking, as well as powder metal 3D printers.

“AI has high strategic relevance for TRUMPF. Our expertise in laser processes and manufacturing helps us to develop smart software for production purposes,” says Richard Bannmüller, CTO of TRUMPF Laser Technology. The system will use the SiMa.ai machine learning system on chip (MLSoC), which run the ML applications entirely on chip. By doing so, this provides a tenfold increase in performance and energy efficiency for both computer vision and generative AI.

The MLSoC AI chips will be integrated directly into the laser systems to use AI algorithms to monitor the quality of the laser welding process in real time and evaluate more than 3000 images per second.

In electric car production, for example, the real-time quality inspection during laser welding with the help of artificial intelligence (AI) is expected to replace separate and complex testing procedures. Battery manufacturers will also be able to increase the quality of their production in real time and reduce the reject rate which could ultimately lower the price of electric cars for consumers.

“The rapid acceleration of AI innovation is reshaping how humans can use emerging technology alongside TRUMPF’s highest level of process understanding, which is enabling AI solutions that drive the industry forward,” says Harald Kröger, head of sales and president of the automotive business at SiMa.ai.

ONLINE PARTNERS