Korean aluminium alloy boosts thermal stability

Researchers in Korea have developed an aluminium alloy for EVs that dramatically improves thermal stability, writes Nick Flaherty.

The team at the Korea Institute of Material Science (KIMS) identified a new mechanism by which the nanostructures inside aluminium alloys work, and the alloys they have developed improve thermal stability by up to 140%, compared with existing aluminium ones.

Aluminium enclosure materials deteriorate due to the heat emitted by batteries, leading to a significantly increased risk of accident as EVs age.

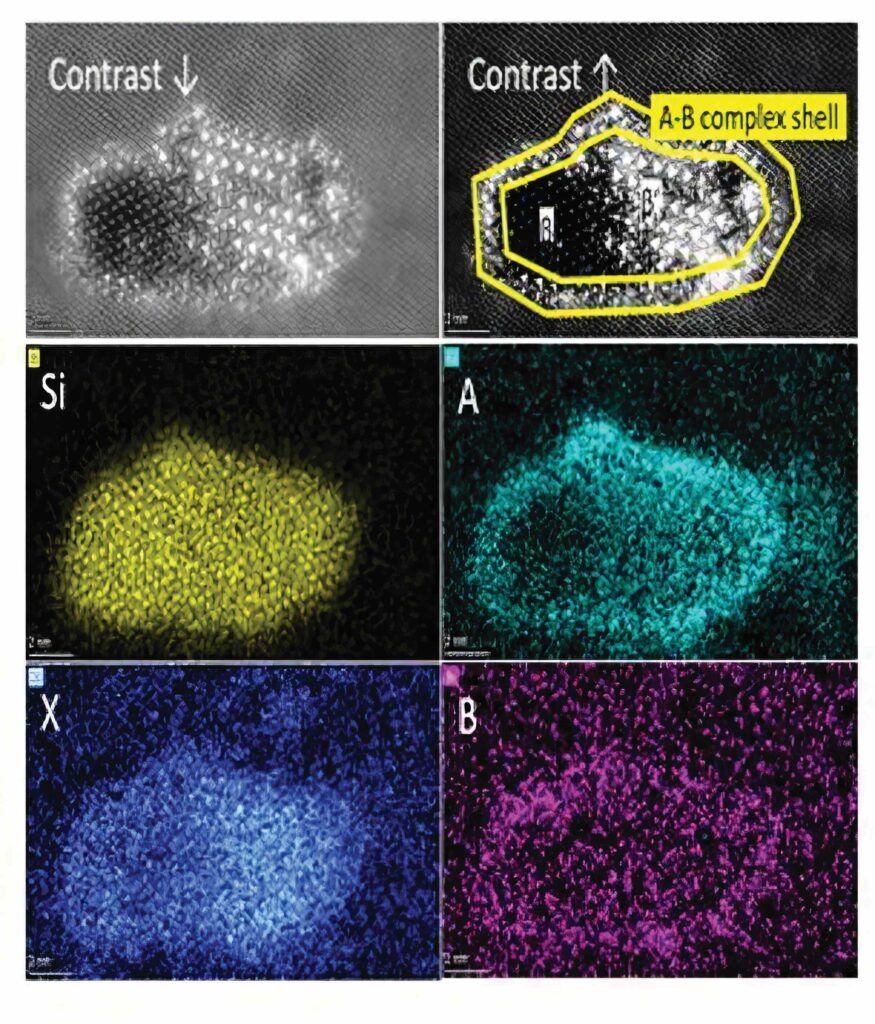

Dr. Hyeon-woo Son and his team from the Department of Aluminium in the Advanced Metals Division at KIMS added trace elements to the existing 6000 series aluminium alloy. They set up a new database by introducing dozens of trace elements and analysing nanostructures using state-of-the-art techniques such as transmission electron microscopy (TEM) and 3D atom-probe tomography (APT). They confirmed that several elements can improve thermal stability.

The team assessed the thermal performance of the AA6061 alloy with trace amounts of silver and germanium using hardness measurements, electrical conductivity tests, TEM and APT.

Trace addition of Ge can increase electrical conductivity and thermal stability, but it also slightly deteriorates hardness during the early and peak ageing stages.

Trace addition of Ag can enhance hardness during ageing, especially in the overageing stage, but it deteriorates electrical conductivity.

As the ageing time was increased, the Ge atoms were incorporated into the precipitates in the alloy, resulting in better thermal stability.

The research is significant in that it expands the database of thermal stability enhancement techniques and introduces new directions for alloy design.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS