Halving the time it takes to roll out battery packs

(Image courtesy of IONETIC)

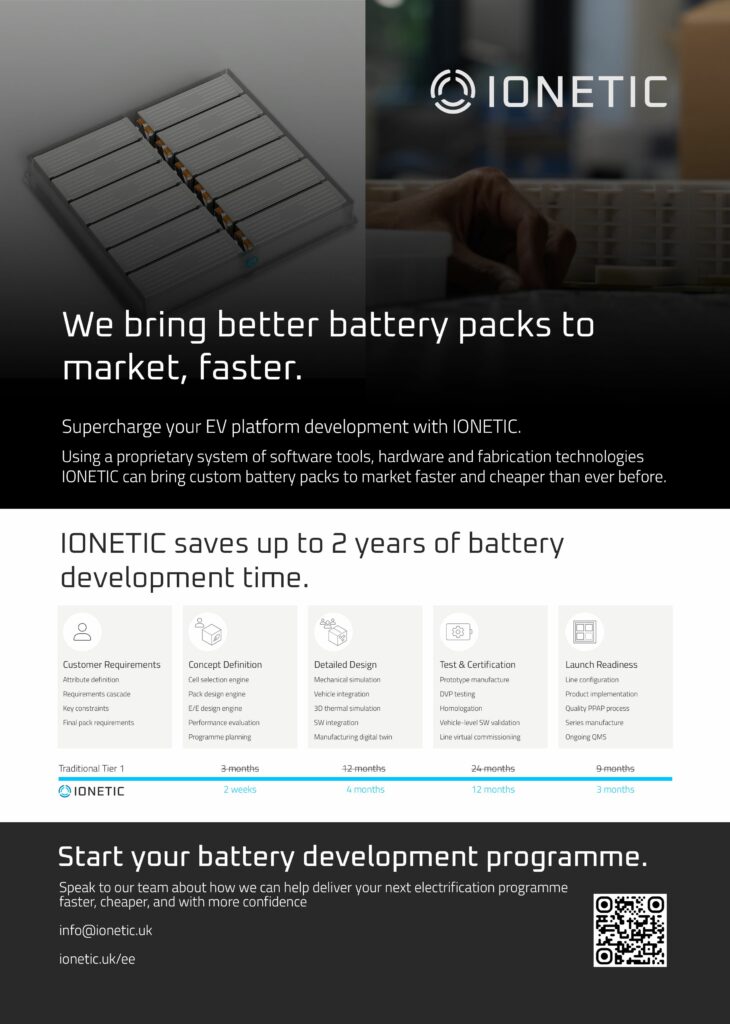

IONETIC has developed a system of software, hardware and manufacturing technologies to simplify the development of battery packs, writes Nick Flaherty.

OEMs needing 100 to 10,000 battery packs a year are faced with a difficult choice: expensive, time-consuming, highly bespoke battery packs or low-performance, off-the-shelf systems.

Arc is a software-accelerated, AI-supported system, designed to halve the development time of a customised battery pack. It is built around a pre-defined design system, including pre-validated components, and supports multiple cell formats. This reduces programme risk and validation time. Arc uses a flexible system, similar to a semiconductor fabrication line, serving multiple customers without the time and cost typically required for a new set-up.

“OEMs need the right partners to bring competitive, electrified vehicles to market as fast as possible,” said James Eaton, CEO and co-founder of IONETIC.

“The Arc system allows us to provide OEMs with pre-validated, tailored solutions, enabling them to remove inefficient development processes, focus on vehicle innovation, and eliminate the usual bottlenecks of cost and time.”

ONLINE PARTNERS