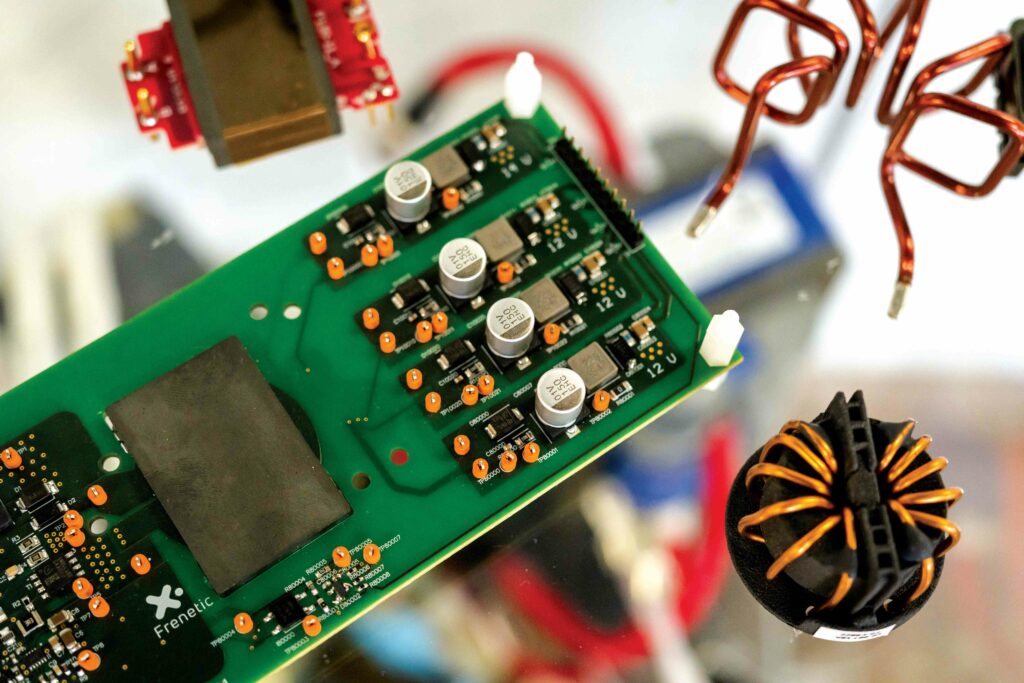

Global production for custom magnetics using AI algorithms

(Image courtesy of Frenetic)

Frenetic Electronics has launched a global production service for its custom magnetics designs, writes Nick Flaherty.

Frenetic Factory produces inductors, transformers and EMI filters, based on a free web design and analysis tool called Core Optimizer. This uses AI-based algorithms trained by the engineers at Frenetic.

“Current methods for designing and manufacturing these components are overly manual, lengthy and iterative. We are using algorithms for ferrite materials and litz wires, and for frequencies from 10 kHz, 15 kHz, to 1.5 MHz, up to 8 E100 stacks to 100 kW,” says Chema Molina, founder and CEO of Frenetic.

“Engineers can choose an inductor, ask for specifications and dimensions, and the algorithm generates a solution or sends it to our engineers for a custom solution – then you can get a quotation.”

One key area is EV charging stations, where the inductors can be very heavy and have a good margin in production batches. “For EV chargers, surprisingly, we are in production for flyback converters and inductors,” Molina says.

The frequency switching is key to reducing the size and weight of the magnetics in a power conversion design, and this is currently limited by the use of ferrites in the tool algorithm.

“If you want to do 2 MHz, the system will work, but the limitation is the ferrite conditions in the L1 algorithm. The algorithms are being updated, and the L2 algorithm in August will cover ferrite and powder, with L3 covering amorphous materials,” Molina explains.

The web-based Core Optimizer tool allows users to compare millions of different magnetics possibilities within seconds, while maintaining the highest level of accuracy. BOMs, 3D models and engineering drawings are automatically generated. Now, users can take that design, and have samples and full production quantities made at Frenetic Factory.

“We have a lab factory in Madrid for everything below 5000 units and we have partners for 10,000 units. We focus on customers that are producing less than 20,000 units a year,” says Molina.

The company has deals with plants in the USA, Mexico, Europe, India and China, and a production capacity of 8.75 million units annually, which can be scaled to even higher volumes.

Frenetic Factory is fully responsible for the technical support and quality of the components it supplies, no matter which facility they were produced in for MIL-STD-461E, MIL-STD-981, ESCC 3201 and AEC-Q200 qualification.

Available core types include ferrite, powder, amorphous, electrical steel and nanocrystalline; shapes include round, litz, foil, planar and Cu-stamped.

ONLINE PARTNERS