Fast charging by crystal seedling

Engineers at the University of California San Diego have developed a high-capacity lithium metal battery that can charge in as little as an hour (writes Nick Flaherty).

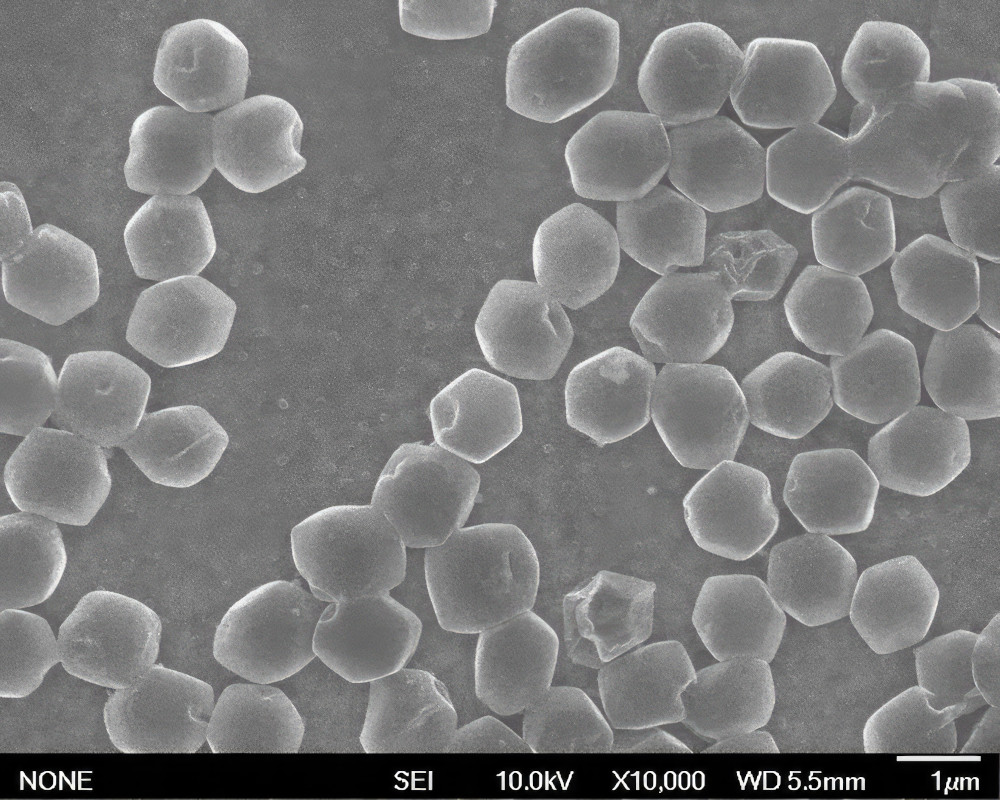

The fast charging is enabled by using lithium metal crystals that can be seeded, and grown quickly and uniformly on a substrate that is different from the traditional copper current collector. The substrate is a nanocomposite made from lithium fluoride and iron, which is lithiophobic – that is, it rejects the lithium ions.

Lithium crystal seeds formed on this surface for lithium deposition, and from them grew dense lithium layers, even at high charging rates. The result was long cycle-life lithium metal batteries that can be charged quickly.

“The special nanocomposite surface is the discovery,” said Prof Ping Liu, professor of nanoengineering at UC San Diego, who led the research. He is also director of the Sustainable Power and Energy Center (SPEC) at the university.

“We challenged the traditional notion of what kind of surface is needed to grow lithium crystals. The prevailing wisdom is that lithium grows better on surfaces that it likes, surfaces that are lithiophilic. In this work, we show that is not always true.

“The substrate we use does not like lithium. However, it provides abundant nucleation sites, along with fast surface lithium movement. These two factors lead to the growth of these beautiful crystals,” he said.

The crystals build up on the iron sites in the nanocomposite as the battery charges, and dissolve as the battery discharges.

A 3 mAh/cm2 cell using a LiNi0.8Co0.1Mn0.1O2 (LiNMC811) cathode, lithium and 3 g/Ah electrolyte cycles at a C1 rate more than 130 times with 80% capacity retention. This is over five times better than the baseline cells using a copper current collector.

Other researchers in the US are also looking at how lithium forms in solid-state lithium metal batteries. One of the challenges with the batteries is that fast charging stimulates the growth of lithium dendrites, which can cause short-circuits.

Professor Yet-Ming Chiang and a team at Massachusetts Institute of Technology (MIT) for example have shown that dendrites can form through the mechanical stress of charging, rather than electrochemical processes, but can be tackled using more stress if it is applied in the right direction and with the right amount of force.

The team showed that they could directly manipulate the growth of dendrites simply by applying and releasing pressure, causing the dendrites to zig and zag in perfect alignment with the direction of the force.

That doesn’t eliminate the formation of dendrites, but it does control the direction of their growth. It means they can be directed to remain parallel to the two electrodes and prevented from ever crossing to the other side; they are thus rendered harmless.

In their tests, the researchers used pressure induced by bending the material with a weight, but in a cell this stress could be applied using two layers of material with different amounts of thermal expansion to create an inherent bending of the material.

Another kind of stress, called stack pressure, is often applied to battery cells, by compressing the material in the direction perpendicular to the battery’s plates, but that actually exacerbates dendrite formation. What is needed instead is pressure along the plane of the plates.

ONLINE PARTNERS