Stackable connectors that simply snap in place

ENNOVI has developed a stackable, multi-row, board-to-board (BTB) automotive connector that snaps together without soldering, writes Nick Flaherty

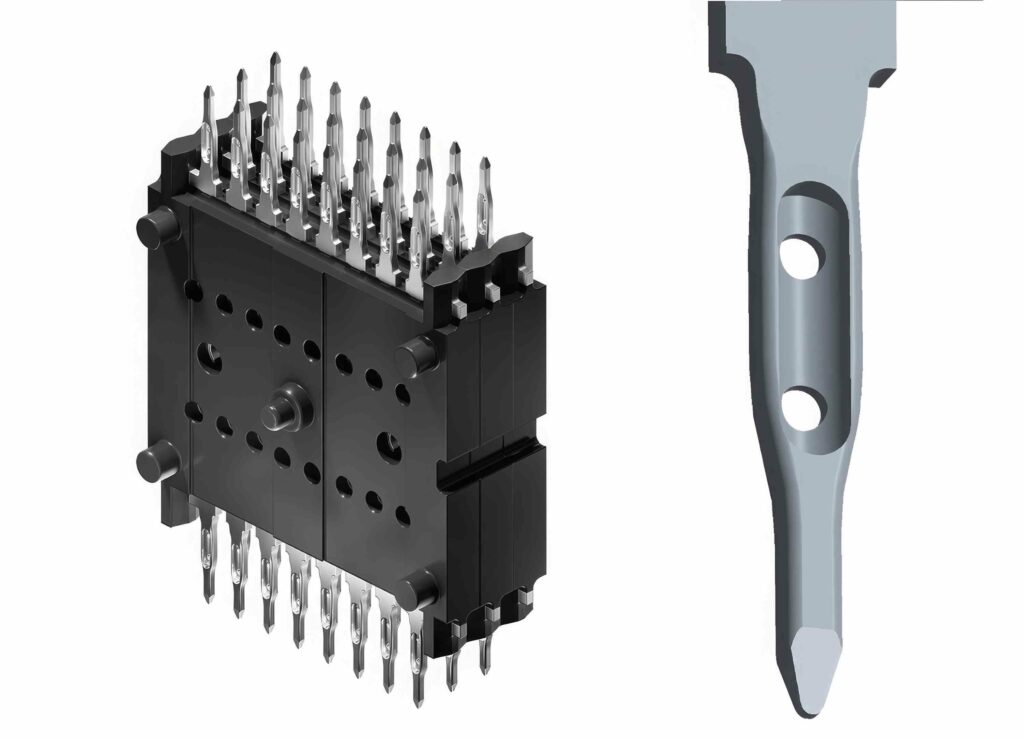

The ENNOVI-MB2B system uses a proprietary ‘snap-in biscuit’ design, which allows multiple connector units to be stacked together without soldering, and it is reliable enough to use in EVs.

The design enables different pin count requirements to be accommodated via the same basic interconnect without any extra expense or engineering effort.

The BTB connectors are based on ENNOVI’s patented, 0.4 mm miniPLX press-fit terminals, which are made from a copper alloy that exhibits low levels of contact resistance at under 1 mΩ. These have an insertion force of under 70 N and a ‘push-out’ force of over 15 N.

Each pin has a 3 A current carrying capability and can be covered with ENNOVI’s IndiCoat plating technology to mitigate the build-up of tin whiskers, which can cause short circuits. The coating extends operational lifespan.

ENNOVI-MB2B connectors come in board-stacking heights of 7-30 mm for Electric Power Steering (EPS) and Electronic Control Unit (ECU) functions in EVs. The connectors can have one to six rows, with up to 30 contact terminals being incorporated into each one.

Conforming with automotive performance requirements, these rugged products can withstand high humidity levels (eight-hour cycling up to 10% RH), mechanical shock (35 g for 5-10 ms across 10 axes) and vibration (eight hours per axis). A working temperature range of -40 C to 150 C is supported.

“Being able to fit enough interconnect terminal pins into a small space while not having any excess is a priority for clients [and] keeping total cost of ownership down is vital,” says Ralph Semmeling, product portfolio director at ENNOVI.

ONLINE PARTNERS