End-of-line battery testing

Covering all bases

As battery technology evolves, so the process of testing it all becomes more complex, as Peter Donaldson discovers

End-of-line (EOL) testing for EV battery packs is a critical step in ensuring their performance, safety and longevity, and that of the vehicles they power. As battery technologies evolve, so do the complexities of testing them.

EOL testing essentially involves a set of tests of a finished product fresh off the production line to ensure that it meets all its performance specifications and doesn’t exhibit any faults before it is shipped to the customer. In the EV battery industry this is generally of cells, modules or complete battery packs, depending on how much of the battery the manufacturer in question builds.

Leading companies such as A&D Technology, Bosch Rexroth, Hahn Automation, Marposs and AVL have developed advanced EOL test equipment that addresses the demanding requirements of these packs.

One of the key challenges is accommodating the wide variety of battery configurations found in EVs. Manufacturers need test systems that can handle different voltages, currents and power ranges, and adapt to specific customer requirements.

“The iTest software is flexible and scalable, with interfaces to over 200 different devices, meaning our platform can adapt to virtually any battery pack configuration,” says Craig Giraud, A&D Technology’s battery test systems (BTS) solutions manager.

Bosch Rexroth takes a similar approach, with its sink/source power electronic solutions designed to handle power ranges from 20 kW to 4 MW and voltages up to 1100 V DC. “Our solution can run in current, voltage or power-control mode,” according to Bosch’s Paul Hickman, ensuring compatibility with a range of battery packs by adjusting based on load conditions.

Hahn Automation offers systems with typical ranges of 400-800 V for battery pack performance tests and a maximum voltage of 10 kV for over-voltage tests. “The system is designed to be scalable. We can adapt to any specification,” say Hahn’s Christian Bubat and Martin Sulzbacher.

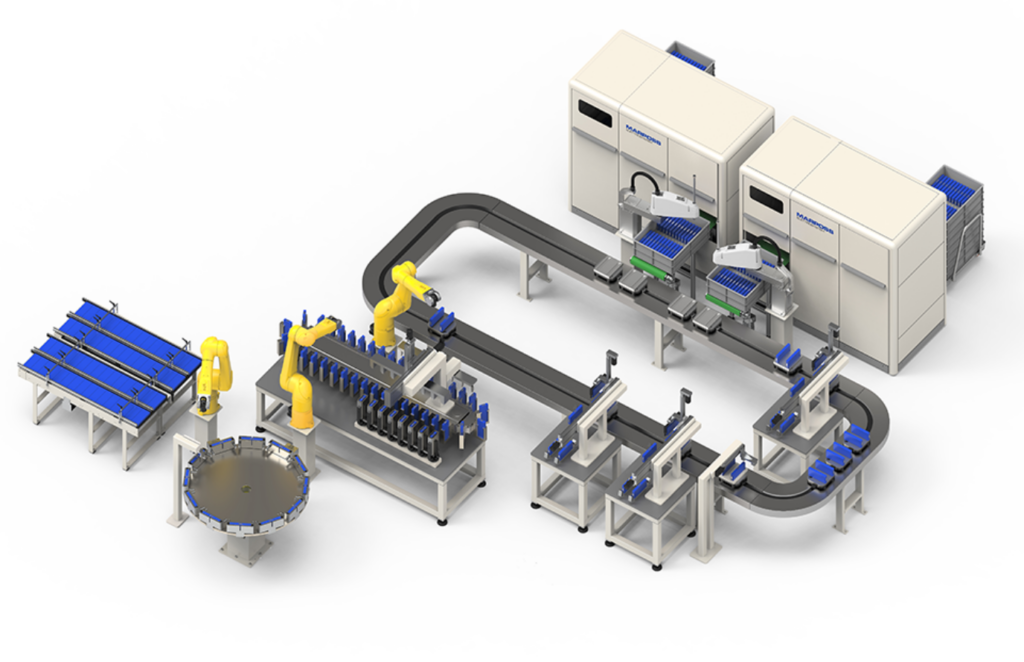

Marposs underscores the importance of customisation, noting that its EOL equipment supports power outputs up to 1 MW and voltages as high as 1500 VDC. “Our systems handle a wide range of power levels, from individual cells to larger packs,” says Pierpaolo Conti, r&d manager for the company’s battery testing department, stressing the need for versatile solutions that can scale up or down, based on the specific component being tested.

AVL offers equipment with voltage capabilities of up to 1500 V and current levels reaching 1000 A. Its systems are designed for power ranges starting at 160 kW and can be extended to over 2 MW by connecting multiple units in parallel. “EOL testing requires robust products to ensure an efficient process,” says Michael Messner of AVL, emphasising the need for high reliability in battery pack testing.

(Image courtesy of A&D Technology)

Safety features

Given the potential hazards associated with high-voltage battery packs, safety is a paramount concern in EOL testing. Each company has developed comprehensive safety systems to mitigate risks such as electrical faults, thermal events and gas leaks. A&D Tech’s iTest platform, for example, enables operators to set their own safety parameters.

“Any input device can be monitored for a user-configurable limit condition, and upon a limit trip, the device under test is placed into a safe condition with HV removed,” says Giraud, highlighting the focus on flexibility and safety.

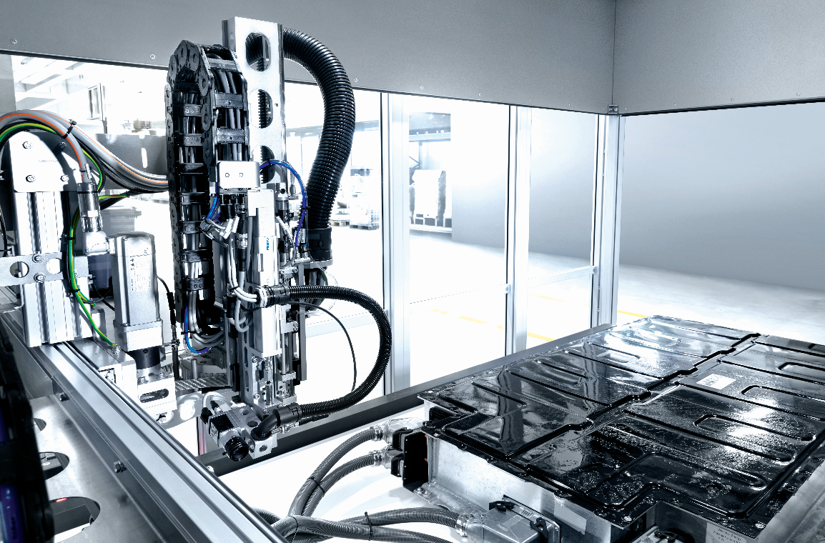

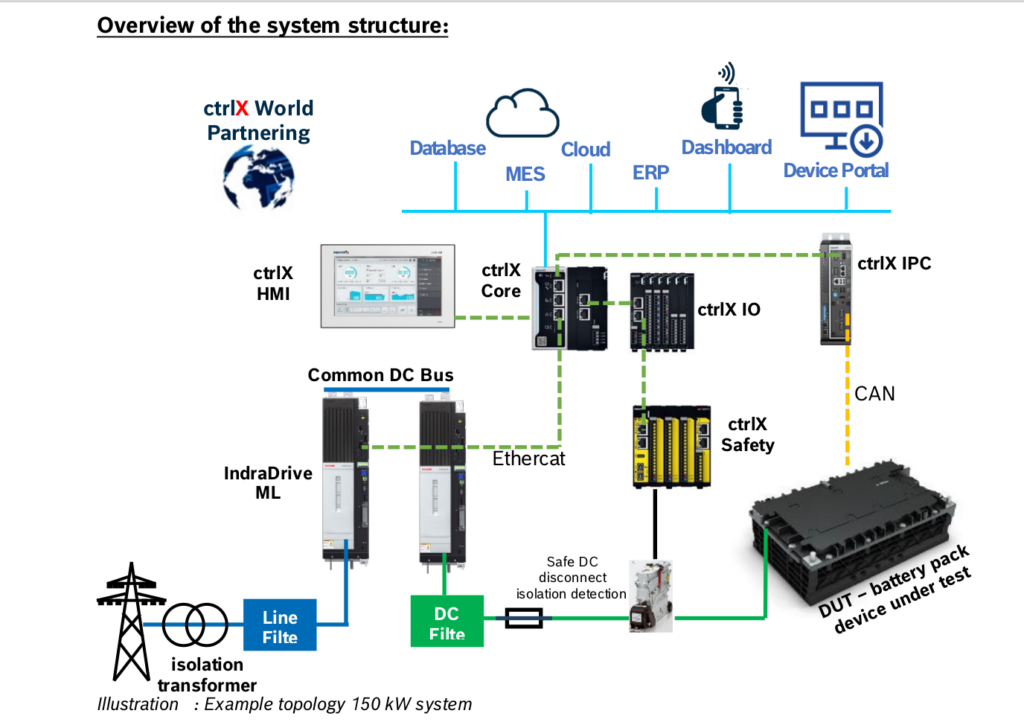

Bosch Rexroth emphasises electrical safety, using galvanic isolation with an isolating transformer and isolation monitoring to detect failures. “The electrical power can be disconnected with safety level SIL 3,” Hickman notes, indicating compliance with the highest practical safety integrity level.

Hahn Automation has taken an innovative approach to safety, particularly regarding thermal runaway. “We have developed a fire-protection cover that can be lowered over the test part if necessary,” Bubat and Sulzbacher say.

This patent-pending cover not only contains the damaged component but also filters flue gases to prevent contamination of the surrounding area. The aim is to ensure thermal events are managed effectively, minimising risk.

Marposs integrates multiple safety systems, including active protection managed by a safety-dedicated programmable logic controller (PLC) and continuous monitoring of battery temperature. “Gas-detection sensors and thermal cameras are often integrated, and active fire-suppression systems are available to handle critical incidents,” says Conti.

AVL’s approach includes a layered safety chain, with its automation system and safety PLC overseeing the entire testing process. “Safety features include electrical insulation monitoring, communication with the battery management system (BMS), gas sensors and infrared cameras for early early detection of developing defects,” says AVL’s Messner.

These systems are designed to ensure any issues are identified and addressed swiftly, preventing damage to both the battery and the testing equipment.

(Image courtesy of Bosch Rexroth)

Adapting to new tech

As the industry shifts towards advanced battery technologies such as solid-state cells, the adaptability of EOL testing equipment becomes increasingly important. All the manufacturers we questioned emphasised that their equipment is inherently adaptable to the variety of cell chemistries and formats and different battery architectures encountered today and to new technologies as they emerge.

Fundamentally, this is because the equipment focuses on measuring the electrical properties of the battery components and systems under test. While parameters such as voltages, current flows, power levels, response times and temperatures are all influenced by cell chemistry, for example, the test equipment applies calibrated loads according to carefully designed profiles and procedures, and then measures how the test articles respond.

Physical parameters of battery packs in particular do influence the test equipment, as large EV batteries are challenging to handle. Bosch Rexroth’s TS 7 transfer system, for example, designed to move packs weighing up to 2000 kg safely.

Marposs emphasises the ease with which their equipment can be retooled for new configurations or technologies. “Adaptation is primarily based on the maximum power specifications,” Conti explains.

A&D states that its iTest software platform cannot only be used with any battery technology but is also independent of specific test equipment, working with the company’s Orion automatic calibration software and its LabWorX lab management software.

“Our modular design approach allows for easy adaptation to future technologies, especially solid-state batteries with higher energy density and improved safety,” says AVL’s Messner. Its regular software updates ensure its systems remain compatible with the latest battery advancements.

(Image courtesy of Marposs)

Multi-parameter testing

For a comprehensive analysis of battery performance, EOL testing often involves simultaneous monitoring of multiple parameters, including electrical, thermal and mechanical characteristics.

A&D Tech’s iTest system uses a shared memory database, allowing it to control and monitor all system activity simultaneously. “Data from the test equipment, BMS, and digital and analog I/O is recorded and combined into a single file,” says Giraud, ensuring seamless integration of test results.

Bosch Rexroth’s systems focus on electrical tests but can incorporate extra parameters if needed. “Additional tests during electrical tests can be realised,” says Hickman, allowing for flexible testing setups based on customer requirements.

Hahn Automation’s system is designed to handle multiple tests simultaneously. “We can perform cooling system tests, communicate with the BMS and run electrical tests at the same time,” Bubat and Sulzbacher note, adding that all tests are coordinated via their proprietary test software, with data recorded synchronously for accurate analysis.

Marposs offers a dedicated product called MAINDO, which manages data collection and analysis for comprehensive test management. “It provides central supervision of recipes, data collection and analysis,” says Conti, ensuring all test data is easily accessible.

AVL’s automation systems are similarly capable of synchronising multiple data streams. “The system processes and synchronises data from different sensors and instruments to provide accurate analysis,” the company says. Its software platforms can correlate data from various tests, helping to identify potential issues early on and reduce testing time.

Storing and analysing data

Data acquisition, storage and analysis form the core of any modern EOL testing system. The ability to gather high-resolution data in real time, store it securely and then process it for analysis is essential for ensuring battery components meet industry standards.

A&D Tech’s approach to data management revolves around its iTest platform, which uses a shared memory database architecture. This allows all data, incoming or outgoing, to pass through the database, ensuring a seamless flow. “At the user’s option, any data can be recorded and stored locally or promoted to a central data repository,” Giraud says, adding that its system is flexible enough to allow analysis through any number of commercially available or user-specific tools.

Bosch Rexroth highlights the precision of its data acquisition system and its focus on high-performance measurement devices that capture data at a cycle time of 1 ms with 24 bit resolution in current, voltage and power measurements. This high level of precision is crucial for real-time monitoring of the battery packs.

“We collect the data in real time and provide it with or without filter algorithms to the external control unit or data storage system,” Hickman notes. The company’s internal control unit, ctrlX Core, offers extensive data-handling capabilities, from the tester to any cloud-based system.

Hahn Automation relies on National Instruments’ CompactRIO (cRIO) system for data acquisition. The company stores all data in a time-synchronous manner in a central database, ensuring it is always available for post-analysis or machine-learning applications. Similarly, Marposs leverages its proprietary product, MAINDO, designed for comprehensive data management, which offers secure data transfers and powerful analysis tools, providing full traceability for battery components during testing.

At AVL, the data acquisition process begins with sensors collecting a variety of signals – electrical, thermal and mechanical – that are conditioned and transmitted to its automation system.

“Data is logged in real time to ensure no information is lost,” says AVL’s Messner. Whether stored locally or in the cloud, this data is crucial for generating quick reports to assess the quality of the testing process and product performance.

(Image courtesy of Hahn Automation)

Industry 4.0 and predictive maintenance

Along with all large-scale manufacturing, firms that make and test EV batteries, and provide the necessary systems for this, are having to come to terms with Industry 4.0. Also known as the ‘fourth industrial revolution’, the expression is shorthand for the ongoing transformation of industrial practices via the integration of advanced digital technologies.

Industry 4.0 is characterised by the use of smart, interconnected systems and data-driven automation to enhance productivity, efficiency and decision-making across the value chain. Its key elements are cyber-physical systems (CPS), the Internet of Things (IoT), cloud computing, artificial intelligence (AI), big data analytics and advanced robotics. These technologies are intended to enable real-time monitoring, decentralised decision-making, and enhanced collaboration between machines, systems and people.

With the rise of Industry 4.0 and the increasing importance of minimising downtime in production, machine learning (ML) and big data management have become critical tools in predictive maintenance for battery EOL testing. These tools allow systems to anticipate failure, optimise maintenance schedules and extend the life of the equipment.

A&D Tech offers LabWorx, an adjunct to its iTest platform, which is geared towards predictive maintenance. LabWorx enables comprehensive data management, tracking test system utilisation and determining preventive maintenance intervals. “It provides revision control on test schedules, scripting code, and any file or document stored in the data repository,” Giraud adds, ensuring the latest information is always available at the test station.

Bosch Rexroth’s ctrlX Core system, based on Linux OS, uses app-based architecture for flexible data-handling, which enables it to incorporate a wide range of Internet of Things (IoT), manufacturing execution system (MES) and data-storage apps for predictive maintenance. “The control unit, ctrlX Core, provides a very wide range of data-handling, from the tester up to any cloud system,” says Hickman.

Hahn Automation integrates AI into its ecosystem of tools for predictive maintenance. “We have the possibility to include AI-based tools, which allow us to carry out predictive maintenance and anomaly analyses, as well as shorten testing time with appropriate models,” Bubat and Sulzbacher say.

By leveraging AI, Hahn Automation can not only predict when a machine is likely to fail, but also optimise testing cycles for maximum efficiency.

For Marposs, MAINDO is the centrepiece of its solution for predictive maintenance. Its flexible software architecture allows seamless integration with big data platforms and machine-learning models in the cloud and onsite. This adaptability ensures Marposs can meet a wide range of prognostic requirements for customers.

At AVL, its software platforms are designed with machine-learning capabilities that support EOL testing. By using advanced algorithms, the company can identify potential issues early on by comparing centrally stored historical data with real-time test data.

“All test components, such as measuring instruments, are connected to the AVL automation system via a common fieldbus to transmit the necessary data for evaluation,” says Messner, helping to schedule maintenance and minimise production-line downtime.

(Image courtesy of Bosch Rexroth)

Real-time monitoring

The ability to monitor testing processes in real time and remotely diagnose issues has become a standard feature for EOL battery testing systems. This capability is essential for maintaining the smooth operation of automated production lines and responding to issues before they escalate into costly problems.

A&D Tech’s iTest system offers real-time operating system (RTOS) capabilities for high-speed data acquisition, as well as seamless integration with MES and Industry 4.0 frameworks via a range of interfaces. Whether it needs to integrate with systems using a component object model (COM) framework, object linking and embedding (OLE) technology, or structured query language (SQL) servers, the iTest platform can be adapted to the specific requirements of customers’ manufacturing execution systems (MES).

Bosch Rexroth has built real-time monitoring and remote diagnostics into the core of its sink/source testing systems. The ctrlX Core control unit offers high-speed communication with MES systems, making it a key player in Industry 4.0 environments. Similarly, Hahn Automation provides a “digital shadow of the line” that enables them to offer full connectivity with other systems, supporting all Industry 4.0 standards.

Marposs underscores its system’s ability to perform real-time monitoring and integrate with MES systems using protocols such as OPC-UA or database table sharing (SQL). This connectivity is crucial for providing accurate, real-time data to operators and engineers on the production floor.

At AVL, real-time monitoring and remote diagnostics are integral parts of its test systems, which are designed for seamless integration with Industry 4.0 frameworks. They collect real-time data without latency, allowing immediate insights and analysis. The use of standardised communication protocols, such as OPC UA, ensures AVL systems can communicate effortlessly with MES and other Industry 4.0 components.

Customisation and user-friendliness

Given the wide variety of battery formats, chemistries and configurations, testing systems must be highly customisable. Furthermore, user-friendly interfaces are necessary to allow operators to configure and manage complex test protocols with ease.

A&D Tech’s iTest system offers a flexible, spreadsheet-based interface that allows users to modify parameters and test sequences with just a few keystrokes. The system includes pre-defined test sequences for standard protocols, such as hybrid pulse-power characterisation (HPPC) and charge/discharge tests, which can be customised by the user.

Bosch Rexroth highlights the flexibility of its system, which is based on its own standards but allows for highly customisable test configurations during the commissioning phase. Similarly, Hahn Automation’s system features an intuitive, ergonomic user interface that enables customers to independently operate the system after a short briefing.

Marposs’s no-code architecture allows users to implement new test cycles without the need for extensive software engineering expertise. This enables rapid customisation of test protocols and parameters, while also benefiting from pre-developed software routines that reduce development time.

Finally, AVL’s EOL testing systems offer both predefined and customisable test protocols. The user-friendly interface includes real-time dashboards that provide immediate feedback on test progress and the scripting language allows operators to create complex, tailored testing scenarios with ease.

Optimising throughput

One of the greatest challenges in EOL testing for battery components is striking the balance between thoroughness and speed. As the volume of EV production increases, manufacturers must ensure that testing processes keep up without sacrificing quality or introducing bottlenecks into the production line.

At A&D Tech, the throughput of its testing equipment is highly dependent on the complexity of the tests being conducted. “Most test steps can be executed in a matter of seconds,” Giraud notes, but factors such as the state of charge (SoC) of the battery at the time can affect the duration of charge/discharge tests. In a high-volume production environment, these variations must be managed efficiently.

Bosch Rexroth highlights a similar point, emphasising that the device under test (DUT) dictates the maximum current or power that can be handled during testing. “The DUT is the master,” Hickman explains, suggesting the specifics of each battery system heavily influence how testing parameters are defined and how fast they can be executed.

Automation is key to improving throughput, as Bubat and Sulzbacher note. By automating part exchanges and parallelising tests, they significantly shorten the time required for each test cycle. Hahn’s systems are designed with a high degree of automation, which means reduced manual intervention and faster overall speed; a factor especially critical in large-scale production.

Marposs takes a tailored approach, working closely with clients to balance the trade-off between speed and thoroughness, ensuring each project’s specific requirements are met. Similarly, AVL uses automated test sequences and parallel testing techniques to enhance throughput while minimising the need for manual intervention. The systems are designed for high-volume, low-complexity testing environments, minimising production line downtime.

Modularity and scalability

As the EV market evolves, manufacturers must frequently adjust to new battery technologies and scale production volumes. This makes modularity and scalability critical attributes for EOL testing equipment.

A&D Tech underscores the importance of software flexibility in scaling their systems. The company’s iTest platform supports a wide variety of third-party equipment, making upgrades simple and minimising downtime when new components are introduced. Its annual software updates typically include new drivers that allow the system to handle an expanding range of battery technologies.

Bosch Rexroth also stresses the modularity of its system, noting that every setup is built according to customer requirements, with scalable options for future upgrades.

Hahn Automation adds that modularity is a core focus in its designs. It offers a standard interface between the EOL station and the workpiece carrier, meaning customers can select the transport system – ranging from manual trolleys to automated guided vehicles (AGVs) – based on their production needs. Its control cabinets have a modular design, allowing varying measuring devices to be installed.

Both Marposs and AVL emphasise the flexibility of their systems in accommodating new technologies. Marposs designs its equipment as modular solutions that can be scaled, both in hardware and software components, while AVL says its systems support incremental expansion.

AVL’s EOL system lets manufacturers start with a basic setup and then upgrade the testing capabilities as production scales up, minimising initial investment while ensuring long-term adaptability.

Global standards

Compliance with international battery safety and performance standards is non-negotiable in the EV industry. Those such as UN 38.3 and IEC 62660 ensure that batteries can be transported safely and meet performance benchmarks. As these standards evolve, manufacturers need to keep their test equipment up to date.

A&D Tech ensures compliance through customer-specific safety systems that continuously monitor for anomalies. Its systems can interface with facility-level safety protocols, shutting down the testing process if any issues arise.

Hahn Automation focuses on using certified measurement devices that comply with the latest standards. Due to the modular design of its systems, it can quickly react to new regulations or customer-specific standards, ensuring its equipment remains compliant.

Marposs takes a proactive approach to compliance, continuously monitoring regulatory developments and industry best practices. Its systems are designed to be updated easily to meet new standards, ensuring that customers stay compliant as regulations evolve.

For AVL, staying compliant involves leveraging its broad range of testing systems, which cover everything from r&d performance testing to environmental and abuse testing. Its equipment supports modular design and tight software release cycles, enabling rapid updates to meet new regulations.

Accuracy and repeatability

Certification tests are essential for verifying battery performance under various conditions, including environmental, mechanical shock, vibration and dielectric strength. Ensuring the accuracy and repeatability of these tests is critical to delivering consistent, reliable results.

A&D Tech’s iTest platform is capable of interfacing with a wide range of certification testing equipment, from environmental chambers to shock and vibration rigs. It verifies the accuracy of its tests through 24 bit, high-accuracy analogue inputs and it offers calibration options on a six-month or annual basis.

For Hahn Automation, its EOL stations are typically used for final testing in serial production, with a focus on dielectric strength tests. They do not typically handle other certification tests such as mechanical shock or vibration in-house, but collaborate with customers for additional testing needs.

Marposs emphasises the importance of defining measurement uncertainty during both the design and qualification phases of its equipment. It operates a dedicated measurement laboratory that produces custom gauges for checking and calibrating its devices.

AVL offers a comprehensive range of testing systems for r&d and EOL testing. Its calibration procedures, automated test sequences and standardised processes ensure its EOL testing systems deliver repeatable, reliable results.

As the EV industry advances, the importance of efficient, reliable and scalable EOL testing for battery components grows. Manufacturers need testing systems that balance high-volume throughput with rigorous safety and performance standards, all while maintaining the flexibility to adapt to new battery technologies and evolving regulations.

ONLINE PARTNERS