Device reads LV and HV in one go

(Courtesy of Ablic)

A 45 V high-withstand voltage battery monitoring device for automotive designs has implemented a supply voltage-divided output for the first time (writes Nick Flaherty).

Dividing battery monitoring between high- and low-voltage sources increases the safety of e-mobility designs, as it allows 12 V batteries to be monitored by the same device that monitors the low voltages of 3.3 V powering an ECU in an EV. This is achieved by converting the high voltage into a low voltage that can be directly input to an analogue-to-digital converter.

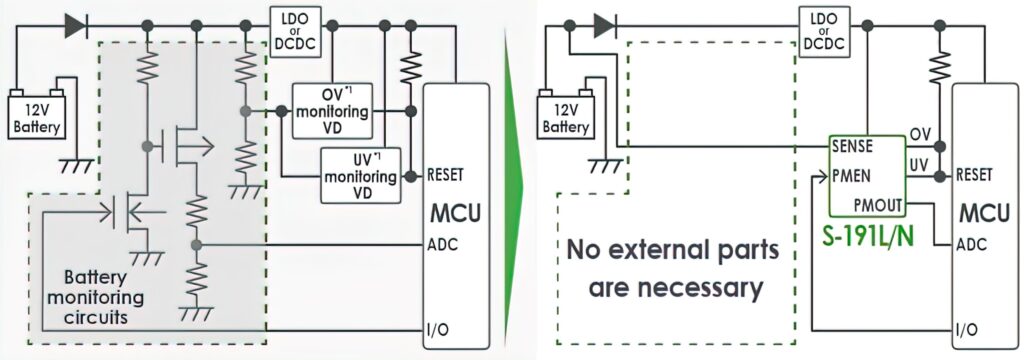

Combining three monitoring functions into a single chip also reduces the footprint required for a PCB and enhances the safety of the system, as there are fewer components that might develop a fault.

The A-191L/N monitor chip from Ablic also includes a circuit for controlling the supply voltage-divided output by turning it on and off to reduce standby current. This reduces the number of external parts and their footprint, and lowers the impact of manufacturing variations of external parts on monitoring accuracy.

The device also monitors low-voltage lines that can be the cause of erratic ECU behaviour or failure, and overvoltage, which can damage an ECU.

An input range of -30 to 45 V on the voltage sensing pin enables the device to handle overvoltage tests or tests simulating reverse connections, providing a means of monitoring the high-voltage output to an ECU by a battery or other power source.

ONLINE PARTNERS