DAFO Vehicle battery fire protection system

(Images courtesy of DAFO)

In a thermal runaway, a lithium-ion battery typically releases oxygen from the cathode and volatile hydrocarbons from the electrolyte, generating both oxidiser and fuel to sustain a fire from purely internal sources (writes Peter Donaldson). Reliable detection and early intervention are therefore critical for preventing the worst consequences of battery thermal incidents – fire and explosions.

That is what DAFO Vehicle has achieved with its safEV system.

As Jonas Bergstrom, DAFO Vehicle’s business manager, bus and coach, explains, “If there is a malfunction in or penetration of a cell, it will start to release gases before the thermal runaway begins. The gases contain a lot of different substances, but we have identified one – carbon monoxide – that is always present, and is independent of the cell type, battery manufacturer and so on. That’s why we have developed the safEV, so that it can detect this gas at a very early stage, on a ppm level.

“Carbon monoxide is interesting because normally it is not present in the environment. There is a low concentration of it outdoors or even in heavy traffic, so it is easy to detect it at the beginning of a thermal event.”

Bergstrom emphasises that the position of the sensor is crucial. “It should preferably be inside the pack,” he says. “For the earliest detection we want to put it inside the case, where the modules are and where the gases will go first. The second-best scenario is outside the pack by the ventilation valves, but of course detection will not be as rapid.”

He explains that the sensor’s detection threshold can be set at between 1 and 1000 ppm. Using CAN bus, it can communicate with the battery management system, DAFO Vehicle’s dedicated control unit, or both. “That is, of course, done in cooperation with the vehicle manufacturer,” he says.

“Then there are different types of action that can be taken. You can just send an alarm to evacuate the passengers from the vehicle, but you can also shut down the affected battery and apply suppression and cooling. If you do that during the ventilation phase then we have a chance to stop the process before the cells go into thermal runaway.”

As well as the CO sensor, the safEV also uses Forrex, a liquid suppression agent with good cooling properties that DAFO developed and has relied on for more than 20 years. Forrex is stored unpressurised in tanks and, when triggered, pressure is applied either from a standalone nitrogen cartridge or a chemical gas generator integrated into the bottom of the Forrex tank, akin to those used in airbag inflaters.

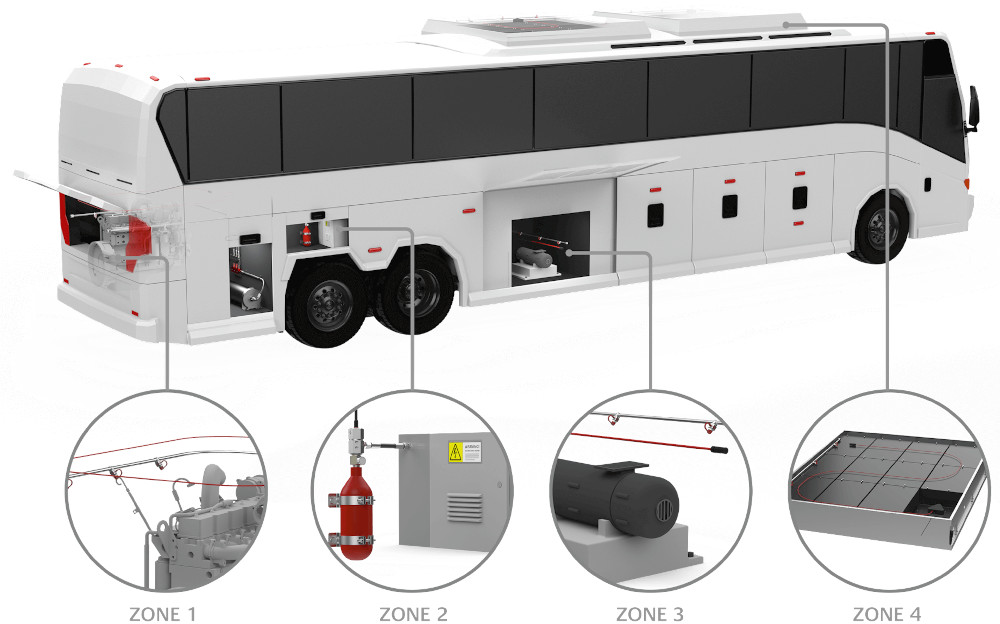

Because e-buses, for example, can have battery systems distributed around several packs, sometimes on the roof, the safEV can be divided into zones so that the control system knows which pack is affected and then act accordingly.

As there is no legal requirement yet to fit battery fire detection and suppression system in these vehicles, the system’s uptake is being driven by awareness among bus and coach operators and, in particular, transit authorities, notes Fredrik Rosen, business manager Europe, Middle East and Africa.

Bergstrom adds that there are about 50 to 60 systems in the field now, but interest is growing. “Companies are becoming increasingly aware of the potential risks, so we are getting more requests for the system. We are focusing mostly on early detection at the moment, because suppression or cooling absolutely requires the system to be inside the battery pack.”

DAFO is 100 years old, but DAFO Vehicle split from the parent company in 2018. “We focus mainly on fire detection and suppression systems for heavy vehicles such as buses, coaches and ‘yellow machines’ such as construction and mining vehicles, and port equipment,” Rosen says. “So we protect all the mobile equipment operating in hazardous areas.”

The safEV system emerged from a research project called Li-IonFire that DAFO Vehicle conducted using funding from the EU Framework Program for Research and Innovation – Horizon 2020, under the SME Funding Scheme.

ONLINE PARTNERS