Cressall unveils liquid-cooled brake resistors

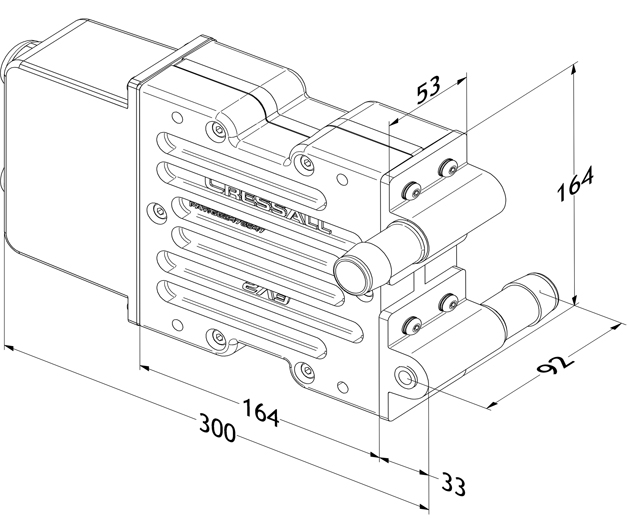

(Courtesy of Cressall)

In electric and hybrid vehicles, regenerative braking is a very effective means of recovering energy by recharging the battery, but sometimes it recovers more energy than the battery can accept (writes Peter Donaldson). This is particularly true for large vehicles such as trucks, buses and off-highway machines on a long run downhill that start with an almost full battery.

The solution is to send the excess current not into the battery but into a braking resistor, or a set of them, that uses resistance to turn the electrical energy into heat and reject that heat into the surrounding air.

To that end, Cressall Resistors has unveiled a family of modular liquid-cooled braking resistors that are much more compact than air-cooled equivalents and provide an opportunity to re-use waste heat.

The company’s technical sales manager Donovan Rannachan says the main purpose of the system is to protect the battery from overcharging during regenerative braking while preserving the braking effect, and energy recovery is a useful bonus.

“Once the system is activated, there are two ways you can use the heat,” he says. “One is to warm up the batteries. In winter, batteries can get cold enough to be damaged, but this system can prevent that from happening. You can also use it to warm up the cabin.”

Rated at 25 kW and 10 kW respectively, the EV2 and EVT resistors for example are based on flat-plate graphite resistance elements in a design that completely separates them from the liquid coolant, which can be pure de-ionised water or a water-glycol mix.

Liquid cooling makes the resistors relatively compact, and they are typically 10% smaller in volume and 15% lighter than equivalent convective air-cooled dynamic braking resistors, which also need dedicated fans. If the extra heat is not needed, because the vehicle is working in a warm environment, it can be rejected to the environment through the vehicle’s main radiator.

Pure water dissipates more heat, so the EV2 for example has a lower rating with water-glycol, of around 18 kW. “You can link up to five modules in a row if the application requires more energy dissipation,” Rannachan says.

Engineering manager Mark Barfield notes that braking resistors are typically used with a brake chopper, a device that regulates when the resistor needs to be in the circuit according to battery voltage. “Once you pass a certain voltage it will then divert the current into the brake resistor,” he says. Cressall plans to offer a brake chopper currently under development by sister company Techmakers with its brake resistors.

Barfield explains that Cressall originally developed its liquid-cooled resistors almost 10 years ago with the EV market in mind, but has sold them into industrial and marine markets while waiting for EVs to catch up. “Over the past 12 to 18 months though we have seen the number of EV-related enquiries skyrocket,” he says.

Most of these enquiries have been from manufacturers of electric buses and trucks, and two projects are currently running under non-disclosure agreements in this area, but Barfield anticipates that car manufacturers will also take an interest.

“Predominantly, we are looking at large vehicles, and that is down to the power involved,” he says. “I suspect that once you get down to small cars and vehicles like that, 25 kW is probably too much. With buses and dump trucks we are looking at something in the region of 200-250 kW, which is quite favourable to our resistors because their space claim is quite small.

“It’s really our first venture into the automotive market, and we found the level of testing and specifications required are beyond what we anticipated, but the work has gone well so far. We’ve passed all the tests and we are working with a lot of OEMs to push it forward.”

ONLINE PARTNERS