Comau joins zero-defect cell-production project

Comau has joined a pan-European energy transformation initiative in the field of e-mobility in support of the BATTwin project.

The company will work with the project’s partners to identify and define crucial data parameters, hardware, software and digitalisation technologies that can be used to meet the goal of zero-defect cell production. Then, it plans to define and implement a multi-sensor data acquisition and management strategy to improve the quality of battery cell manufacturing.

Funded by the European Commission within the framework of the Horizon Europe research and innovation programme, BATTwin aims to develop a multi-level, digital-twin platform that will help reduce defect rates in lithium-ion battery production, which is expected to reach up to 30% during the ramp-up phase of Europe’s new gigafactories.

With the goal of reaching zero-defect manufacturing, the digitalised virtual environment will be deployed and tested in-field to validate its flexibility, scalability and effectiveness. The programme is coordinated by Professor Marcello Colledani of the department of mechanical engineering at Politecnico di Milano, Italy.

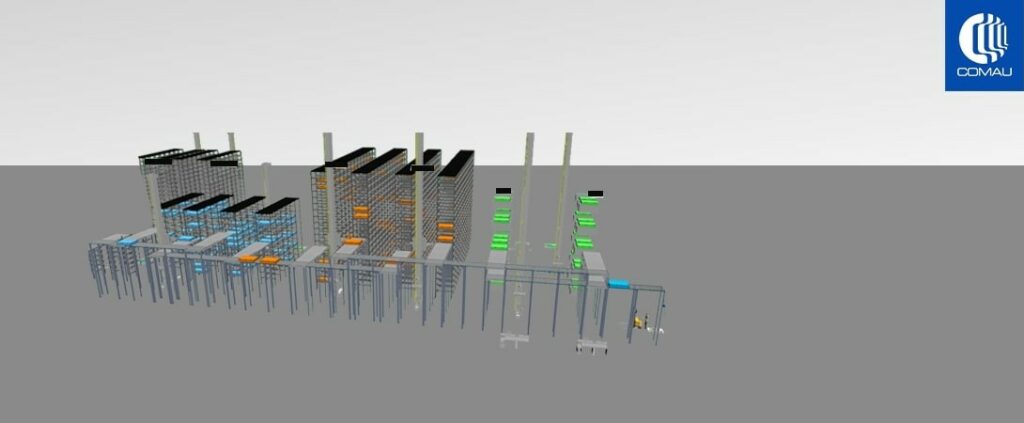

Under the scope of the project, Comau will leverage its long-standing expertise in digitalisation, digital twinning, process simulation and electrification to enable automatic data acquisition and transmission to a cloud-based virtual environment.

The company will perform discrete event simulation (DES) modelling at production level, and develop a digital twin for the production system design and redesign. This will enable cell manufacturers to optimise their workflow, analyse cycle times, prevent bottlenecks, and manage both energy consumption and manufacturing performance at machine level. The continuous information feed means manufacturers will be able to instantly recognise and prevent potential production issues.

“This ground-breaking project, which was conceived within the framework of various Upcell discussions, aligns perfectly with our future-focused technology roadmap,” says Daniela Fontana, battery innovation manager at Comau.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS