BEDEO van conversion

(Image courtesy of BEDEO)

Reborn electric

Peter Donaldson discovers how conversion packs are putting electric powertrains inside diesel vans

One of the greatest benefits of electrified light vehicles is the elimination of tailpipe emissions and the consequent improvements in air quality in urban areas. Large vans form a key part of the ‘last mile’ logistics that keep cities running. However, Osman Boyner, founder and CEO of BEDEO, argues that today’s electric vans do not meet the needs of the market, while even diesel vans that do meet the latest Euro VI legislation still produce significant emissions.

BEDEO group company Protean Electric’s in-wheel motor technology enables a conversion package that adds an electric powertrain to existing diesel vans, as well as an option to convert to full electric. Dubbed the Reborn Electric RE-100, the package is designed for vans in the EU/UK N1 and N2 categories, which cover vehicles up to 3.5 t and 4.5 t, respectively.

“Commercial fleet operators face a number of challenges, not least the uncertainty of a moving government deadline for an all-electric future,” he says. “While switching to an all-electric fleet is desirable, it is also very expensive and wasteful, requiring investment not only in the vehicles themselves but also in the infrastructure to support them.”

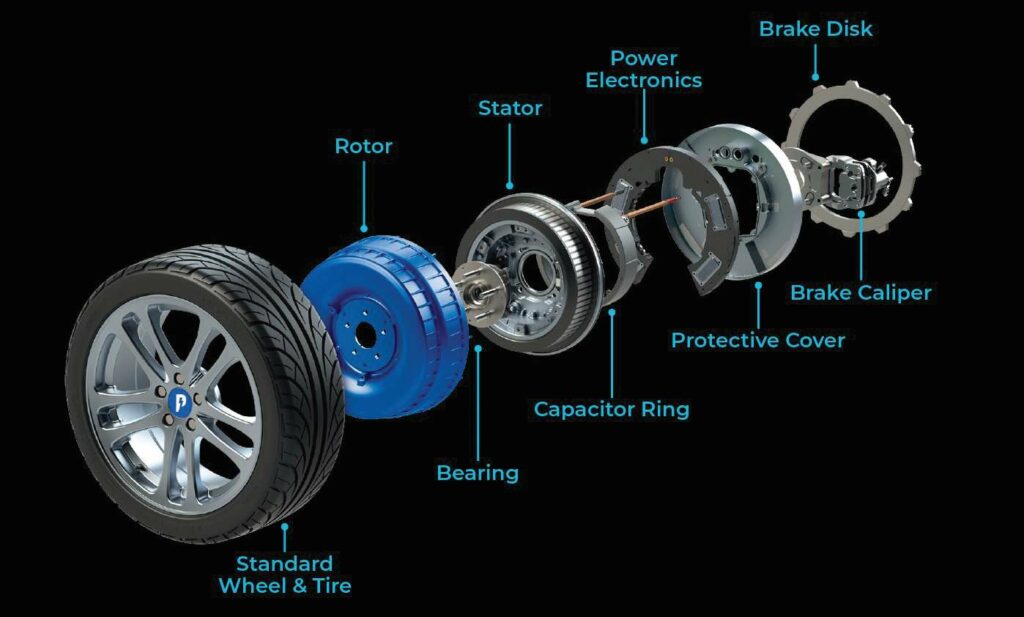

(Image courtesy of Protean)

Life extension

Boyner points out that the whole lifecycle of a vehicle must be taken into account when judging the overall sustainability of the transport system, making conversions more attractive.

“It cannot be sustainable to replace a vehicle that has not reached the end of its useful working life; neither is it sustainable to replace not only the vehicle but also the bespoke equipment fits that many of these vehicles have,” he says.

When planning the RE-100’s development, Protean researched how much fleet owners spend on equipping their vehicles, coming up with an average of £10,000 per van, according to CTO Stephen Lambert.

“That takes costly installations such as refrigeration into account, all the way down to racking for tools, etc. If you are running a standard panel van, the system may not work out to be cost-effective for you, but it fits those fleets that have more bespoke vehicles and ‘backs’ so you can extend their lives.”

In the UK alone, the number of commercial vehicles on the road is nearly five million, of which 55,000 were battery electric at the end of 2023, Boyner says. “This leaves a massive number of combustion engine vans on the road, which will either continue emitting pollutants way past 2035 if they are kept, or will be scrapped, wasting valuable, usable materials. Retrofitting offers a practical solution to extend their lifespan and transform them into EVs.”

Intended to be used around town, particularly in low-emission zones, the RE-100 conversion retains the unmodified diesel powertrain for longer runs. The add-on electric powertrain’s major components are the battery pack and the Pd18 4250 in-wheel motors.

Lambert says that although these components add weight and reduce payload in those terms, it doesn’t have a significant impact on the range achievable with the diesel engine, particularly in a vehicle designed to carry weight.

“We don’t change the fuel tank, so the fuel volume remains the same, and the battery and other ancillaries are installed underneath the vehicle, so we don’t impact the load capacity in volume terms,” he explains.

Boyner says that although the driver of an RE-100 can choose which form of power to use under most circumstances, the system prevents operation in diesel mode within controlled low-emission zones unless there is an emergency. “Outside controlled zones, the driver is in control and can determine when to stay in electric power for a more pleasant driving experience, or switch to diesel for longer distances.

(Image courtesy of Protean)

In-wheel motor development

For the last 15 years, Protean’s technology development has centred on in-wheel motors, and Lambert emphasises that it is protected by more than 300 patents in Asian, European and North American markets. This focus on intellectual property (IP) is part of a policy to build trust among partners in the global automotive industry.

Protean’s inventions address many aspects of the technology, including mechanical design, robustness against vibration and shock, sealing, thermal management, power electronics and their integration, motor sensing and control, electromagnetic design, fault tolerance, manufacturing tools, brake integration, and the control of in-wheel motors for performance and safety. Perhaps the core of the company’s development efforts is the integration of the inverter into the motor.

The overall concept is to integrate everything that would normally be on the axle into the wheels, Lambert explains. “An e-axle would be made up of a transmission, an inverter or multiple inverters, and a motor or multiple motors. We’ve designed the motor to fit inside the wheel, and then we have integrated the inverter in there, saving a lot of space. And that’s really where our value proposition is: enabling our customers to do more with their vehicle platforms,” he says.

BEDEO, which bought Protean from National Electric Vehicle Sweden (NEVS) in 2021, does the vehicle conversions, taking Protean’s in-wheel motor technology and its own components and integrating them into the vehicles.

“These two elements are separate, but there is a lot of benefit in cross-pollination among the group, where there may be a deeper understanding of something in one area than the other,” says Lambert. “Protean might need to understand how something is integrated on the vehicle and we can go to BEDEO for that, and if they want to understand a piece of electronics or some detailed mechanical design, they can pull that from Protean.”

As well as conversions of used vehicles, it will be possible to order brand new ones with the system installed, Lambert says. BEDEO is both a customer and a partner, but Protean also works with other OEMs. “There’s nothing stopping our technology being used in OEM-supplied vehicles, as well as retrofits.”

The RE-100 conversion has been designed to affect the rest of the vehicle as little as possible and to keep the installation process relatively simple. The battery in its enclosure is attached under the floor of the cargo area, and it is connected by cabling to the motors with their integral inverters in the wheels on a new rear axle.

(Image courtesy of Protean)

Simple conversion

This simplicity makes the conversion process fairly quick, but it will vary depending on how much, if any, refurbishment needs to be carried out. “The estimated time is in days or weeks, not months,” says Lambert.

Perhaps surprisingly, the suspension mostly escaped the need for modification, despite the extra weight inside the wheels.

“What we have learned is that the unsprung mass isn’t that big an issue. Some small modifications to the suspension can help, but really, it’s only in high-performance vehicles where you’re ever going to notice anything. To some extent, higher unsprung mass can help with damping down the effects of pothole strikes or curb strikes, for example,” Lambert explains.

“Equally, it’s about the ratio of sprung mass to unsprung mass, so if you’ve got a commercial vehicle weighing 3 t or 3.5 t, adding a few kilos to the unsprung mass isn’t going to make much difference.”

The conversions are not limited to front-wheel-drive vans, but at the moment they are offered for the Citroen Jumper, Fiat Ducato, Opel Movano and Peugeot Boxer, with the Renault Master and Mercedes Sprinter coming soon.

As with most hybrids, the RE-100’s battery pack has a fairly modest capacity of 37 kWh, giving the van a range of 117 m on electric power, plus 600 km with the range extender when measured according to the Worldwide Harmonised Light Vehicles Test Procedure (WLTP).

It is based on a lithium nickel manganese cobalt oxide (NMC) cathode chemistry and designed for commercial vehicles. “Battery technology is at a level now where you don’t have to push the boundaries to meet the majority of user requirements,” Lambert says.

The priorities for the battery technology were led by value for money for the customer, he says. In performance terms, meeting the gradability requirements for a fully loaded commercial vehicle was the most important thing.

Cooled by a standard 50/50 water/glycol mix, Protean’s motors (EME 003, Summer 2019) are permanent magnet synchronous radial-flux AC machines with an external rotor. This architectural choice was the result of a lot of engineering analysis, Lambert says.

“It is really about trying to come up with the highest power density that can fit in the wheel space at an acceptable cost. There are other machine topologies that might give you a higher torque density or a higher power density; you could look at an axial-flux machine, for example. The problem is that starts to increase the cost because of the amount of magnetic material you need, so we really think we are in the sweet spot for cost and performance for in-wheel motors,” he adds.

(Image courtesy of Protean)

Sealing challenge

The main technical challenges during development involved sealing and making sure the motor worked reliably in all use cases.

“It’s quite a harsh environment down there by the wheel, so we do a lot of testing, wading through water, running in ice, exposing it to extremes of temperature and vibration as well,” he says. “In the wheels, there is a lot of high-frequency as well as

low-frequency, high-amplitude vibration that you have to take account of. Now, we have a reliable product that can survive in that environment.”

In addition to the vibration, sealing the motors against the ingress of contaminants such as water and dust is critical. Part of the challenge here, says Lambert, was designing a seal that would keep contaminants out while keeping any drag torque that it imposes on the motor to a minimum to preserve energy efficiency.

“You’re going to put some additional drag torque on the motor with any part that has to seal against a rotating surface, but we have been quite successful with our low-resistance seal,” he adds.

Protean’s motors are of the out-runner type, meaning that the rotor housing is on the outside and revolves around the central stator. The seal, therefore, has to keep contaminants from passing through the gap between them around a relatively large circumference compared with seals needed for in-runner motors.

According to one of Protean’s patents, the seal is a ring with a V-shaped cross-section. Made of a rubber material such as neoprene, it makes use of centrifugal force to minimise friction and ensure an effective seal. When the rotor is stationary or rotating slowly, the seal fully closes the gap, but at higher speeds the seal is forced away from the stator housing enough to minimise drag torque and wear due to friction, while the centrifugal force prevents the ingress of contaminants.

Integrated bearings

The motors integrate the wheel bearings, making the whole assembly more compact, and this contributes to its stiffness and strength, with wheel bearings being inherently strong components. Lambert notes that while the bearings are fairly simple, getting them right presents some complications, with different versions of the motor distinguished by bearings with varying load ratings, and the higher-rated bearings naturally used in commercial vehicles.

A further consideration involves remaining compatible with standard vehicle systems that connect with the wheel bearings, such as wheel speed sensors.

The motor is designed to be compatible, with standard wheels and tyres. Looking inwards from the wheel, the first component encountered is the rotor. This is attached to the rotating portion of the wheel bearing, independent of the studs that hold the wheel on. The stator is attached to the non-rotating portion of the wheel bearing and supports the field coils. On the other side are the capacitor ring (more of which later) and its two DC cables, the inverter and the cover.

The brake caliper mount bolts through to the non-rotating portion of the wheel bearing, while the brake disk is secured to the rotor with a set of bolts around its circumference and is gripped by the caliper from the inside. The entire assembly bolts to the suspension arm.

The rotor and the stator are made from an aluminium alloy that gives the motor the ruggedness it needs at a price point that fits the market. The remainder of the bill of materials is accounted for by the magnets attached to the inner surface of the rotor, the copper windings, the ‘back iron’ core that supports the windings and completes the magnetic circuit, and the power electronics of the integral inverter.

The inverter inside the motor takes the form of two curved modules attached to the back of the stator. The inverter is electrically connected to a large capacitor that smooths out the fluctuations on the DC bus when the motor is operating in regen mode and supplying current to the battery.

So far, so conventional, but because the inverter installation has to fit into a small, cylindrical space, the capacitor cannot be a large, square block, Lambert points out. Therefore, Protean designed the capacitor and its connections with the inverter as a large-diameter ring, which is referred to as an annular capacitor.

Three-phase inverter

Rated at 400 V, the inverter is a three-phase unit, based on silicon insulated-gate bipolar transistors (IGBTs) rated at around 750 V. “We buy those in from one of our technology partners who we’ve been working with for a while. They provide us with integrated power modules, which we then attach and weld into the inverter,” Lambert says.

Using IGBTs capable of handling voltages higher than the inverter’s nominal rating provides some margin for it to cope with any voltage spikes and transients safely, and to allow for manufacturing tolerances that affect the components’ real-world voltage limits. The idea is to enhance the inverter’s reliability and longevity.

Protean is looking at alternative power electronics technology in the form of silicon carbide MOSFETs for use in future inverter systems, Lambert notes.

Even with the inverter integrated into the wheel motor, the positive and negative DC cables, CAN bus wires and coolant lines unavoidably enter the wheel hub, so their routing and protection are among the factors that must be considered in engineering the system to meet reliability and longevity goals.

“Doing all of this in the wheel is very hard, but our advantage is that we have been doing it for 15 years and we have understood the issues,” says Lambert.

Broadly, solving these issues involves providing protection for inherently delicate components and engineering the rest to be as tough as they can be.

He explains: “Where you’re designing something from scratch, you design it to be as robust as possible, and when we’re buying something in and integrating it – typically in the electronics – it’s more about ruggedising it as much as possible. What you don’t want is components falling off the PCB, so the vibration becomes quite a severe design constraint. You have got to work with your suppliers to make sure they can build assemblies that will be suitable for the application.”

Complexities arise as components of varying sizes made from different materials can resonate in response to different forcing frequencies, and understanding this is crucial.

“You can narrow it down by looking at the high-risk items and anything with a high mass or a high moment as a result of where it is being vibrated from, particularly if it is sticking out from its support and could resonate loose,” Lambert says. “Again, we know where to look and what sorts of mitigations to put in place.”

Because the RE-100 has independent drives for each wheel, it must meet a higher Automotive Safety Integrity Level (ASIL), as defined under the ISO 26262 standard, than would a conventional e-axle with a single motor, transmission, differential and inverter.

“As soon as you have those independent drives for each wheel, you are in ASIL-D territory, so your starting point is always going to be the most stringent automotive functional-safety level,” Lambert says. “Working with the industry, particularly with our OEM customers and BEDEO, to understand how the motors are integrated into the vehicle helps us a lot in developing our safety strategy for the motors.”

An important element of the safety strategy relates to how the motors are integrated into the vehicle’s electronic stability programme. Protean has built demonstrator vehicles to study the impact of torque vectoring and traction control, for example, in high-performance applications, and Lambert says these read across well to the more prosaic world of commercial vehicles.

“Understanding how those things work at the limit of grip on high-performance vehicles helps us to design a safer commercial vehicle,” he says.

“The advantage of in-wheel motors is that they can respond very quickly, compared to an e-axle.” (The company quotes a response time for the Pd18 4250 of 2 ms.) “They don’t have the compliance and twist in the shafts that go to the wheels, so the only real constraint on how quickly we can impact the torque delivered to the road is the flex in the tyre itself.”

Accelerated testing

The RE-100 is designed for a service life of 300,000 km or 15 years, and Protean is going through a rigorous, accelerated life testing programme to ensure it meets that requirement. “It’s accelerated, but it still takes weeks and months, and it is harsh testing that takes in all the edge cases as well,” he says. “It’s not enough to make sure it will survive 300,000 km in the best of conditions, but the worst-case realistic conditions as well.”

This means exposing the RE-100 to the kind of shock loads that would be generated when hitting a large pothole or striking a kerb, along with extremes of temperature. “You go down to -40 C a number of times. You assume it will see that number of very low temperatures in its life, and some high temperatures too,” he says. “We’re close to completion.”

Development has been done and deals signed with lead customers for delivery this year. Testing is an ongoing process, however, and is principally focused on new-use cases.

“We’re still finding different applications and vehicles that these motors might be used in, which may throw up new testing requirements for us,” Lambert says.

Looking further ahead, Protean is looking for optimising tweaks that will improve efficiency. “That may mean changing components or tuning how we are using those components to ultimately give our customers the best possible solution from a range, efficiency and cost point of view,” Lambert adds.

The major components of the hub motor revealed, with the integrated wheel bearing, capacitor ring and brake being notable design features

ONLINE PARTNERS