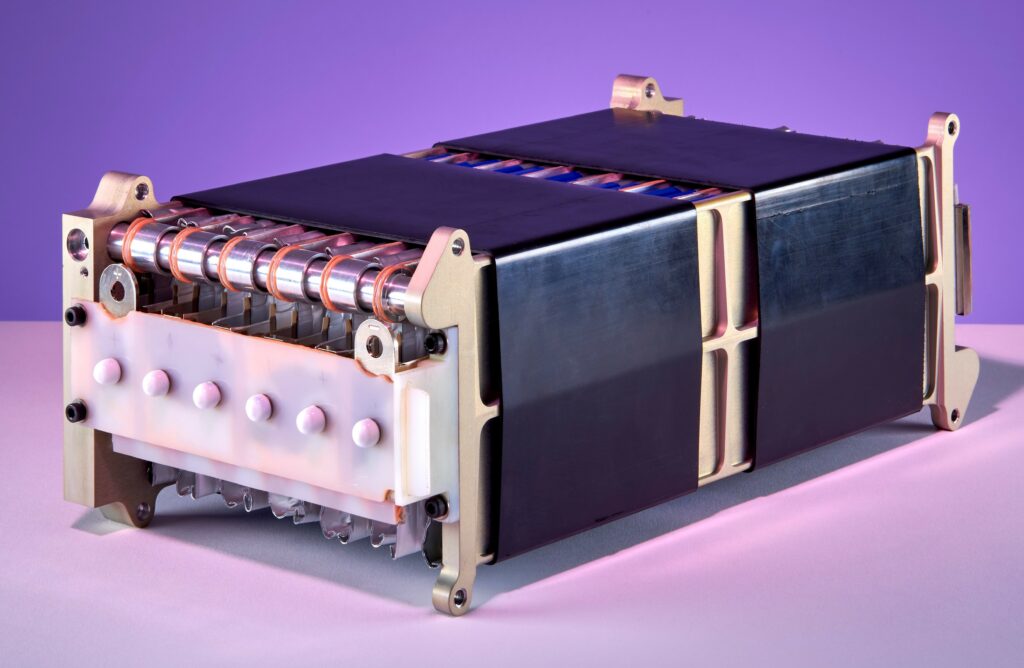

Balance Batteries shares details about its range of modules

(Courtesy of Balance Batteries)

Balance Batteries, a new Tier 2 supplier of battery modules, recently unveiled its energy storage solutions and spoke with us exclusively to highlight the technologies used in them – some of which are supplied externally, and some developed in-house (writes Rory Jackson).

As a manufacturer and integrator of battery technology, Balance has established links with advanced cell developers. Through this supply network, its engineers have found four different cells with identical sizes and shapes but varying power and energy capacities.

“That has allowed us to create modules ranging from 444 Ah to 684 Ah, which also have different power capabilities,” comments Doug Cross, managing director at Balance Batteries. “There is a high-energy module that is able to run at 2.5C, for example, while a high-power module discharges at up to 5C.

“As a result, we can develop battery packs from our modules that, when plotted on a graph of specific power against specific energy [kW/kg and kWh/kg respectively], can be tailored for use on fully electric vehicles or on PHEVs across a range of applications, including in aviation as interest in eVTOL and eSTOL grows.”

Three modules have been announced, all of which contain 12 cells that can be connected as 12S1P, 6S2P, 4S3P, or 3S4P depending on voltage, current and other requirements.

The 11 kg PHEV module integrates 37 Ah cells, enabling it to discharge up to 8.1 kW continuously from its 1.62 kWh maximum capacity. The 10 kg Fast Charge module is built with 49 Ah cells to hold 2.15 kWh maximum and discharge at 8.6 kW – while producing far less heat than the other two across its current output range – and the 10 kg BEV module uses 52 Ah cells to store up to 2.28 kWh and output a maximum continuous 6.8 kW.

Also, although choosing an optimal cell is crucial to creating a battery module with high power and energy capabilities, the battery’s ability to supply high continuous power without overheating depends on the efficiency of the thermal management system. A poorly designed or over-engineered cooling system will add excess volume and weight to an EV’s powertrain.

To that end, Balance Batteries is developing and patenting a cooling architecture for its systems.

“We start with an inlet at the bottom corner for a liquid cooling medium, which runs up vertically until the fluid enters a channel with six cooling fins running across the module,” Cross explains.

“Each fin is in contact with two cells, to conduct heat into or out of them as needed. The fins are only 2 mm thick, and are made out of three aluminium sheets: a blank top plate, a blank bottom plate, and a serpentine shape running in between them designed to maximise contact between the coolant and points where heating or cooling will be needed most.”

Extensive modelling has been performed to ensure enough thermal transfer for running the cells as hard as is feasible. In addition, the company has paid close attention to the even distribution of clamping pressure within the modules.

For instance, a foam sheet is installed in the pack to increase top-down compression of the cells, and ensure that the pressure is distributed evenly. That is key to preventing them from delaminating internally owing to gas generation during high-temperature operation, and some studies indicate that this might also enhance their electrical contacts and capacities.

“Finding a sheet with the right combination of compressibility, output pressure and thermal conductivity is something we spent a lot of time on,” Cross adds. “In addition to the foam sheet, we’re also using elastomer sleeves tied around the groups of cells for low-cost and lightweight clamping of our modules.”

ONLINE PARTNERS