AZL Aachen invites firms to join rotor sleeves project

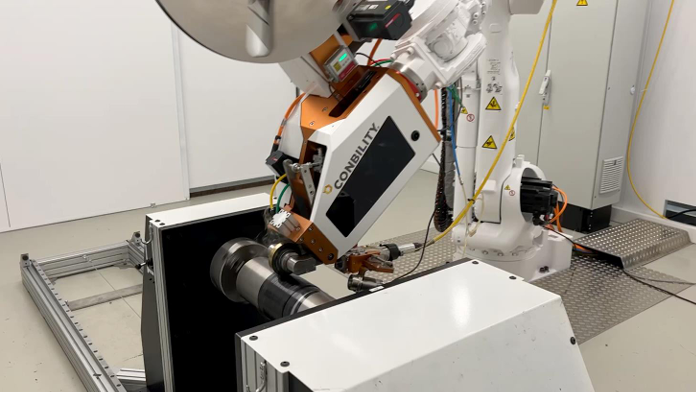

AZL Aachen has announced a Joint Partner Project, focusing on the technology for reinforcing electric motors with fibre-composite reinforcement sleeves.

The nine-month scheme will investigate current and future applications for electric motors, their requirements for armouring sleeves and provide technological insights. Interested companies can join the consortium, which includes Kümpers, Rassini and Schunk Kohlenstofftechnik, until the kick-off on September 12.

The project, Rotor Sleeves for Electric Motors: Potentials for Composite Materials and Technologies, aims to address the growing demand for more efficient, powerful and compact motors.

Composite rotor sleeves offer very high stiffness, low density, almost zero thermal expansion and favourable electromagnetic properties. They are expected to expand into mass applications for EVs, power tools, machine tools and electric aircraft.

“As a manufacturer of composite materials, we develop and produce customised towpregs and prepreg UD [unidirectional] tapes for a wide range of applications. With increasing demand for efficient electric motors, the importance of rotor sleeves in mass production has increased, which achieve a very high level of performance, particularly when processed with towpregs.

“The AZL Joint Partner Project is a promising opportunity to gain impulses for the further development of our material and market expertise… we look forward to expanding our network and discovering new solutions,” says Dietmar Hoffstedde, expert for composite towpregs & prepregs at Kümpers.

AZL will bring together experts from across the value chain to investigate current and future applications, analyse requirements, and assess the impact on design, material selection and production concepts. Throughout the project, participants will gain a comprehensive understanding of rotor sleeve technology and its applications in electric motors.

ONLINE PARTNERS