Thermal management

(Courtesy of Kia)

Heat exchangers

Peter Donaldson talks to industry experts about the latest advances in EV thermal management technologies

Users of EVs of all kinds, and battery EVs in particular, want more range and/or running time, faster charging and greater assurance of safety. Thermal management is central to all these.

We approached industry experts to gauge the emerging technological solutions to these high-level requirements. They are varied, and represent subtle changes and larger scale transformations, complementary developments and major divergences in architectures and heat transfer materials and methods.

An expert from an electrification specialist reports strong interest from industry customers in developing solutions that allow the heat generated by the motor and power electronics to be captured and reused for other functions, such as heating the cabin or warming the battery, which helps to reduce parasitic losses and extend range.

A further trend the expert identifies is the desire to improve the volumetric efficiency of the battery by making the cooling solutions more compact. He says that by using two-sided cooling, for example, OEMs can reduce the number of cold plates required, which frees up space for additional battery capacity to increase range.

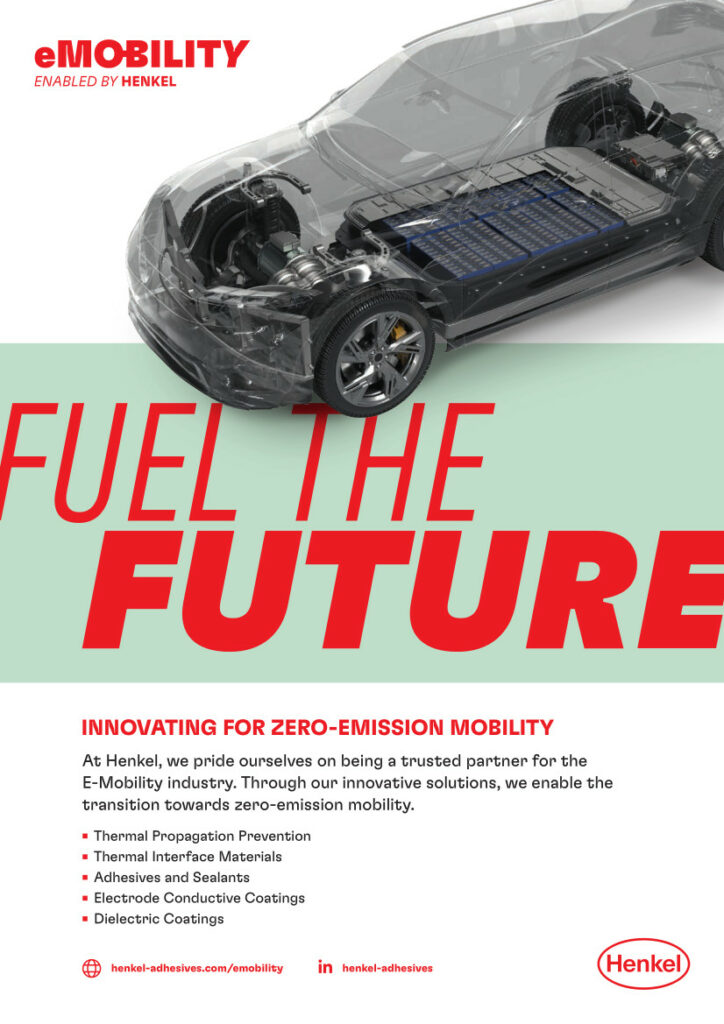

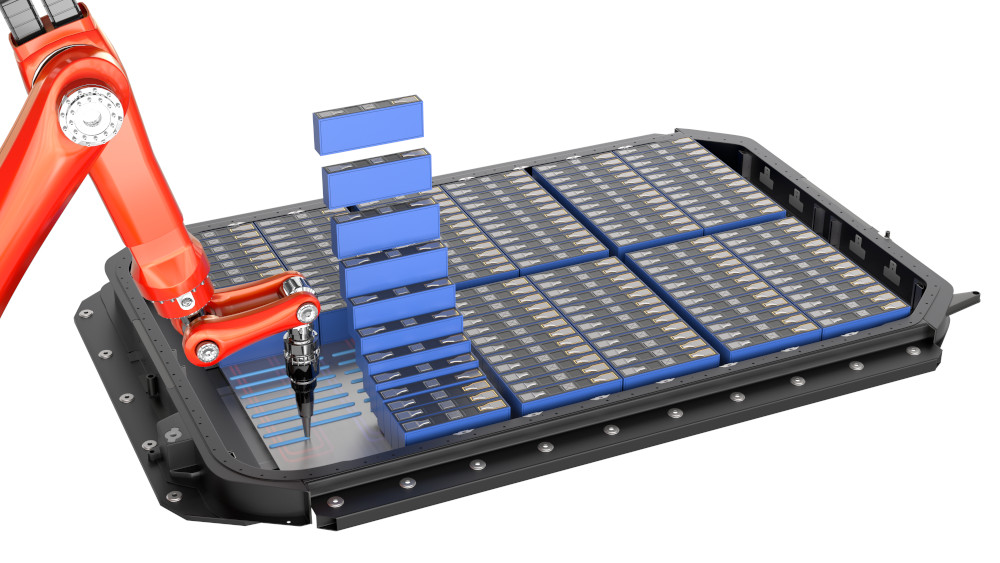

Evolving cell technology could also have a major effect on thermal management, explains a specialist in thermal interface materials, adhesives and sealants. He adds that this will lead to redefining many aspects and requirements regarding designs for performance and safety.

Overall, the specialist says, optimising battery pack design for higher energy density, weight and cost reduction will drive significant changes in the requirements for thermal interface materials. He points to the development of cell-to-pack and cell-to-chassis battery architectures as examples.

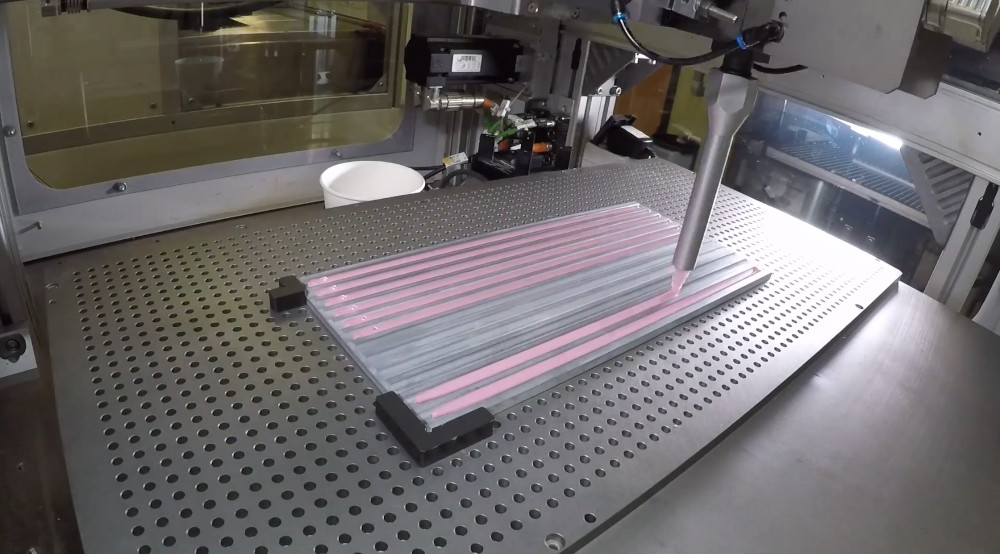

(Courtesy of Dana)

This design approach, he argues, will bring requirements for thermally conductive adhesives that contribute to efficient thermal management and crash-relevant structural integrity. At the same time, the adhesives will have to be de-bondable on demand to address repairability and ease of recycling, as these are defined by and become enshrined in regulations.

Another thermal management materials specialist says the weight saving offered by cell-to-pack architectures is achieved by eliminating numerous steps, parts and materials when batteries no longer require module housings in addition to the main case, and individual cells are bonded directly to cooling plates.

Battery manufacturers and OEMs are also looking for alternatives to silicone-based thermal management materials in some applications. Solutions based on other chemistries including urethanes, epoxies, modified silane polymers and acrylics, in addition to silicones, are therefore becoming increasingly important.

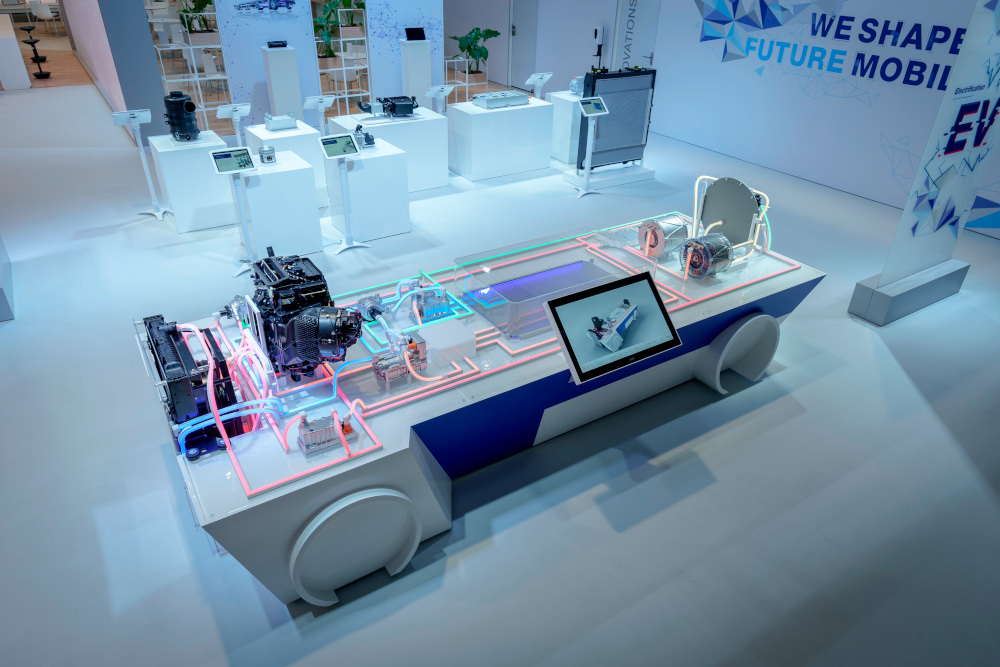

An automotive powertrain specialist with long experience in IC as well as electric powertrains emphasises that the thermal differences between the two have a major impact on systems design, and are driving closer integration.

“The absolute temperature in an EV’s cooling circuit is much lower than in a combustion engine,” he says. “Initially that is a disadvantage for the performance of the cooling system, since the temperature gradient – the difference from the ambient temperature – is lower. At the same time, while the heat input into the cooling system is less than that of a diesel engine, for example, the difference is not as great as might be assumed.”

Electric motors, power electronics including inverters, and transmissions also generate waste heat and add to the number of components that need cooling. Further, the powertrain specialist notes, the collected heat must be used carefully in EVs, for example through the use of heat pumps in cold weather to avoid immediate loss of range. He adds that keeping battery temperature within a narrow window to avoid loss of performance and even material damage is a challenge that can also apply to motors and power electronics.

“As a result, conventional cooling systems are no longer sufficient,” he says. “Coupling the refrigerant circuit of the air-conditioning system to the overall thermal management of the drivetrain is therefore absolutely necessary. That applies all the more to situations that cause increased thermal stress, such as charging at very high rates.”

He continues by saying that many components must be actively heated when cold, but the waste heat from the exhaust gases from an IC engine are missing, so heating processes consume energy. “Thermal management is therefore becoming increasingly complex energy management issue, but the fundamental functions of an EV depend on it.”

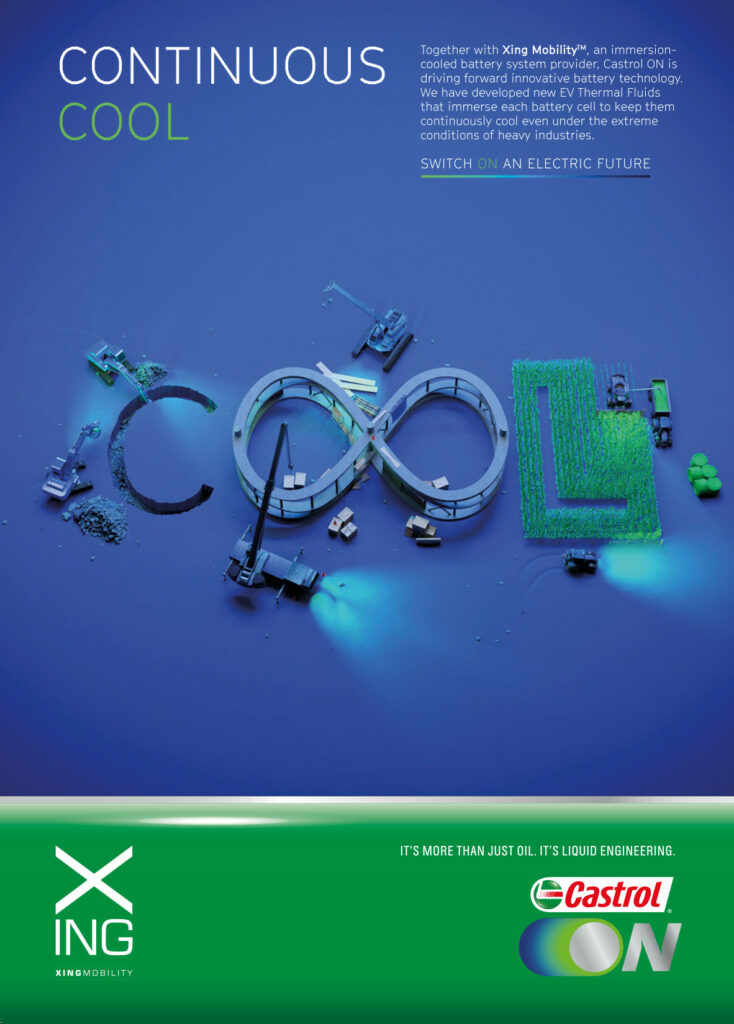

A significant advance in heat transfer materials that also affects battery pack architecture is the development of dielectric fluids that make direct contact with the cells and their electrical connections.

One specialist we consulted says a battery pack with cells immersed in electrically non-conductive (dielectric) but thermally conductive fluid can keep cell temperatures within an optimal range more effectively than indirect cooling with conventional fluids, even with rapid charging and exuberant driving. He adds that this also protection the cells from degradation, helping to enable fast charging and longer battery service life.

“We have also shown that dielectric thermal management fluids are effective at preventing thermal propagation should a single cell go into thermal runaway,” he says.

Architectural effects

The growing demands of thermal management are affecting the way the architectures of powertrain subsystems and of vehicles as a whole are designed.

(Courtesy of Henkel)

The fluids specialist notes that efforts to maximise power and energy density have led to the need for aggressive thermal management. He says that EV traction inverters and power converters for example are designed with wide-bandgap semiconductors that operate at high temperatures, while the effort to increase range is pushing the adoption of higher energy densities in cell chemistry as well as battery pack design.

“As a consequence, heat generation increases, and removing this extra heat becomes more challenging,” he explains. “Traction battery designs that maximise active material content, such as cell-to-pack, need direct cooling to ensure minimum thermal gradients. Traction motors designed to maximise the direct exposure of coil windings to the cooling media achieve significant improvements in power density.”

The expert from our vehicle electrification specialist says that perhaps the biggest change comes in the form of subsystems integration. Customers are looking at how they can save by combining functions that have similar thermal management needs, such as charging and power conversion, into integrated power modules, for example.

“By improving the packaging of these components, we can manage the thermal requirements of these systems more efficiently and economically,” he says.

As this trend strengthens, powertrain developers are moving towards solutions in which the e-drive, inverter and onboard charger are integrated into a so-called smart box, the thermal interface material specialist notes. “The main aim is to combine various functionalities at the controller and power level in comprehensive designs for lighter and more efficient operation,” he says.

This both dovetails with and promotes the integration of previously separate powertrain cooling and air-conditioning circuits into unified thermal management systems.

This seemingly ever-closer integration raises the question of how early in an EV’s design process its thermal management system should be considered in detail.

The automotive powertrain specialist emphasises that because of the strong influence that thermal management has on the performance and service life of system components, as well as the required overall energy efficiency, it must be taken into account early in vehicle development.

The fluids specialist emphasises that this should happen right at the start. “If the fluid is considered as a component in the same way as, say a pump or a manifold, then a much more optimised design is possible,” he says. “Through this kind of co-engineering approach, any potential synergies that exist between the fluid and hardware can be readily exploited.”

Faced with the different heat generation rates associated with components that find themselves packaged in close proximity, EV developers are striving to find one-fits-all solutions and ideally a single thermal management fluid. “Dielectric thermal management fluids might open up novel thermal management options for the vehicle manufacturers,” the fluid specialist notes.

In the best case, developing enabling technologies such as thermal interface materials, gap fillers and adhesives should run ahead of mechanical design concepts so that dedicated thermal management solutions can be integrated optimally, the expert in these materials says. “The target should be to have smart, high-performance, cost-efficient solutions engineered in from the start, rather than having to solve a thermal problem at the end of the design path,” he explains.

He also states that design for manufacture and overall process engineering are important for ensuring that the final systems can be produced quickly, efficiently and sustainably.

“Battery pack designers, engineers and manufacturing teams should involve thermal management suppliers at the pack design stage to ensure that the right materials are selected, and that manufacturing feasibility is considered,” the second materials specialist adds.

Click here to find out more about Castrol On EV Fluids

Runaway prevention

Preventing or mitigating thermal runaway is, naturally, a vital part of thermal management, and the materials and technologies that contribute to this are developing rapidly.

“The most important improvement we have seen in this respect is the emergence of lithium iron phosphate [LFP] battery chemistry for mainstream EVs,” the fluids specialist says. “LFP battery chemistry is inherently safer than the nickel manganese cobalt-based chemistries that are dominant these days, owing to its higher chemical and thermal stability.

“However, although it costs less, LFP hasn’t often been used because of concerns about its lower energy density, leading to lower ranges, but these have been addressed through cell-to-pack engineering. As such, we have seen major European EV manufacturers start to move towards the use of LFP for some of their models.”

He also highlights the importance of the latest battery management systems to safety, emphasising that they have improved dramatically since the first modern EVs emerged, and can now safeguard the pack from conditions that could cause thermal runaway.

“They can also implement mitigation strategies when a thermal event is detected, such as activating the thermal management or electrically isolating the damaged cell,” he says. “Combining that with an immersion cooling system can offer even further improvements owing to the improved heat transfer.

(Courtesy of Mahle)

“Advanced electrolyte engineering will increase the temperature required to enter thermal runaway compared with current electrolytes. That will become very important as battery energy density increases.”

The electrification specialist’s expert emphasises the importance of managing heat conduction, particularly by controlling its direction in a thermal event.

“While cold plates are efficient during normal operations, they have the drawback of providing a conductive path for heat during thermal runaway,” he notes. “An intelligent design approach that limits lateral conduction can slow down the progression of thermal runaway between cells.”

In addition to the long-anticipated shift to solid-state cells, the thermal interface materials, gap fillers and adhesives specialist says there are products available or under development that can be applied at battery pack level for propagation prevention in a thermal event. These include hybrid and multi-functional materials that combine resistance to high temperatures with thermal isolation in lid coatings, cell pads, compression pads and potting foam products.

“Depending on the cell type and the overall battery pack design, these products are combined into solutions to help protect passengers and to contribute to the required evacuation times,” he says.

An aerogel blanket manufacturer notes that cell-to-cell (C2C) barriers made from these materials have gained popularity for delaying thermal propagation in battery packs containing pouch or prismatic cells.

“Aerogel-based C2C barriers can act as both a compression pad and a firewall between adjacent cells. Accomplishing this in the slimmest package possible is critical to meeting energy density and range targets. As the world’s most efficient insulation material, aerogels are uniquely well-suited to this safety-critical application,” an expert from the company explains.

Aerogels are solids with the lowest known thermal conductivity. The material comes from the manufacturer as a blanket capable of withstanding temperatures up to 1400 ºC and of preventing C2C conduction of heat with blankets as thin as 2 mm.

Integrated functions

(Courtesy of Castrol BP)

Innovations in battery design, particularly the integration of electrical, thermal and structural functions into enclosure components to improve pack-level energy density, will also affect thermal management.

The automotive powertrain specialist regards that as a trend worth monitoring, arguing that multi-function components can reduce parts counts and simplify battery pack manufacturing processes. “That leads to different solutions depending on the requirements, ranging from immersion-cooled battery systems to cooling structures integrated into the battery housing,” he says.

The fluids specialist, for example, favours this approach, arguing that immersion cooling with dielectric fluid enables optimised pack designs.

“For example, busbars can get quite hot under high-power charging events. If these can be cooled by the dielectric fluid then they can be made smaller so less material is used, saving weight and cost,” he says.

“Getting rid of dedicated cooling loops by bringing the electronics closer to the pack will improve energy density, but care should be taken with the dissimilar temperature limits between cells and power components. Direct cooling of electronics can boost the pack energy density even further, as the electronics can be downsized.”

The company is a partner in the UK’s APC18-funded Celeritas programme, which addresses this concept, he adds, with the aim of producing battery packs for hydrogen fuel cell hybrid vehicles as well as for full battery EVs.

The vehicle electrification specialist says the battery enclosure is a promising target for reducing the complexity in EVs. The company is developing a composite battery case that promises a reduction in weight of up to 30% compared with a metal equivalent, and integrates the cooling path routing and cold plate, sealing, and heat shield functions.

One major challenge in this area will come from reducing the number of load-bearing structural components inside a battery pack. The thermal interface materials and adhesives specialist argues that while having fewer module parts will free up more space for cells in the battery, it will also create a need for more and better bonding materials.

He stresses that these materials will have to be multi-functional, have long service lives, high bonding strength and solid thermal performance. They will also have to withstand the stresses placed on the structure during operation, withstand impact loads and be de-bondable for repairs. The company has a team dedicated to developing such materials.

“Early engagement in concept and design discussions is even more important here, because the battery pack will be relevant to the vehicle’s crash performance, and therefore so will the thermal management materials and components,” he adds.

Cooling power electronics

(Courtesy of Parker Lord)

High-performance power electronics present challenges that require new thermal management approaches. Both our materials experts emphasise that the needs of inverters, DC-DC converters and onboard chargers are as important as those of other major components in the powertrain, and that this reinforces the case for involving them early on to optimise the operation of the vehicle as a whole. Critical issues for early discussion include thermal conductivity, viscosity and compatibility with electrical components.

Early involvement improves understanding the overall system design concept, while providing more time to evaluate the wide variety of products and matching them to critical needs such as high-voltage isolation, tolerance of harsh operating conditions and high temperatures.

“In our view, the best strategy would be direct cooling with dielectric single-phase fluids in a spray or impingement system,” the fluid specialist says. “That is because these cooling methods allow significant reduction of thermal resistance and a lower pumping power demand, and they can be integrated with other EV drivetrain subsystems such as the traction motor, e-drive and geartrain.”

Another approach to cooling power electronics is the use of an internal diverter plate, the electrification specialist says. This can produce uniform temperatures across all the power modules in an inverter, for example, reducing the risk of excessive temperatures in chips.

“With the increased interest in the use of new wide-bandgap semiconductor materials, such as silicon carbide, thermal management systems will need to be designed with high heat flux in mind,” he says. “Simulation tools can help reduce the development time by modelling how the coolant is distributed.”

He points out that his company’s cooler designs can have components soldered directly onto them, eliminating the need for thermal interface materials and the associated thermal resistance. “We achieve this by offering direct-bondable aluminium designs featuring a thin layer of copper applied,” he says.

The design of cooling plates and heat sinks is also evolving, and is an area in which metals still have a lot to offer. That is particularly so when the volume available for them in a battery pack or module enclosure is at a premium, according to experts from a Tier 1 thermal management system supplier with a long history in the automotive industry.

The company primarily designs thermal management and fluid conveyance solutions, and has developed liquid-cooled battery cooling plates, some of which are up to 2 m long, using various materials and manufacturing methods. A recent thermal management system developed for a passenger car application, which is now moving into series production, features two formed aluminium plates brazed into a single assembly, on which battery modules are placed. This solution maximises design flexibility, coolant control and battery performance, the experts say.

“The temperature differential between the hottest and the coldest cells can be as low as1 ºC, so we are getting good performance out of this design,” one of the experts says. “It is essential to have even cooling distribution. You want to maintain cell temperature within extremely tight tolerances, to optimise performance and avoid battery degradation.”

The company designs, develops and manufactures thermal management system components for electric, hybrid, and IC powertrains. A recent example is a tubular coolant manifold for a truck OEM, manufactured from 0.7 mm-thick stainless steel. The original customer specification was for a mild steel part coated to protect it from corrosion, but the development process revealed that the part would be more cost-effective if it were manufactured from more expensive stainless steel, as the coating and its application process made the mild steel part costlier overall.

The company also makes heat sinks for power electronics using either copper or aluminium, with copper preferred for high-performance applications. One example is designed to cool the IGBT board in a power converter and features patented fins shaped like the Greek letter omega, a configuration well-suited to rapid charging applications because it limits the temperature increase more effectively.

Fuel cell-based propulsion systems are the focus of intensive development to replace diesels in heavy truck applications, and their thermal management needs present their own set of problems. The automotive powertrain specialist notes that although a fuel cell-based drive is more efficient than a comparable diesel powertrain, most of the waste heat goes directly into the coolant. A further complicating factor is that the resulting coolant temperature is lower, so the cooling system has to work harder to reject an equivalent amount of heat energy.

“We are talking about a factor of 1.5 to 2 for the required cooling capacity compared with the combustion engine,” he says.

What’s more, he says, the optimum temperature for a fuel cell is around 70 ºC, which is particularly challenging in high ambient temperatures. Taken together, all of this means that the thermal management systems architecture can be even more complex than in in battery EVs.

Fuel cell management

The main thermal challenge with fuel cells, according to our fluids specialist, is maintaining a constant operating temperature for the polymer exchange membranes to operate at peak efficiency.

He explains that the cooling medium is deionised water, which is used because the membranes are very sensitive to ‘poisoning’ by the ions in tap water, for example, and to the degradation of metals in contact with it. Deionised water is a relatively corrosive liquid, so careful selection of compatible materials during systems design is essential. In addition, the plates need uniform cooling if they are to be efficient and durable.

Materials issues

The move towards higher power and energy densities in EVs also affects the development of thermal interface materials, compression pads, encapsulants, gap fillers and adhesives used in the powertrain’s subsystems.

The need for heat transfer across the interface between surfaces in particular has grown, and it is becoming more important to ensure rapid and efficient removal of heat from more thermally sensitive components such as cells, power switch substrates, magnetics, passive components and the insulation of motor windings.

(Courtesy of Senior Flexonics)

The first materials specialist emphasises the importance of smart design, regardless of the material involved, to optimise weight and cost. Materials dispensed in liquid form, such as gap fillers and potting compounds, dominate assembly processes, while the use of pads as the primary certified isolation is undergoing something of a renaissance in powertrain systems.

“Selecting the right product together with the proper process should drive the final decision, because there are so many thermal interface products available,” he says.

One important aspect of optimising heat transfer is maximising the effective contact area between the heat transfer material and the component, the fluids specialist argues.

“Dielectric thermal management fluids offer advantages in this respect, because the entire system can be immersed in an effective heat transfer fluid,” he says. “There is also much less need for thermal transfer materials, because the hot surfaces are in direct contact with the fluid. That means more heat can be removed from a greater surface area compared to an indirectly cooled system.”

High-voltage ancillaries

A further trend in EV thermal management systems is the move to power components such as coolant pumps and heat exchanger fans from the high-voltage supply, which has implications for the system as a whole.

Powering any component from the high-voltage supply makes it more efficient because of the reduction in ohmic losses resulting from the reduction in current for any given power level, the fluids specialist points out. Being more efficient, he adds, the pumps and fans can deliver more cooling power.

“Ultimately, EV manufacturers will implement a thermal management system that meets the cooling and heating requirements of the vehicle at the right cost,” he says. “Using more of the pack energy to cover more miles and less to power auxiliary components will be a differentiating factor.”

Being able to run the cooling peripherals at higher power will certainly have a significant and positive impact on cooling system efficiency, the first materials specialist notes. With EV designers targeting high charging rates – a full charge in 10 minutes in 800 V systems, for example – optimising the power of the cooling system will help to operate cells at lower and more uniform temperatures, increasing the system’s robustness and reliability.

Developing the next generation of systems is focused on eliminating energy consumption from components that are not in use, the automotive powertrain specialist notes. “For example, eliminating the energy use from valves and sensors can help to increase the energy efficiency of the entire system,” he says.

Polymer effects

The use of polymers in battery module and pack structures will have an impact on thermal management systems. The main driver here is reduction of the overall mass of the pack without sacrificing structural integrity, but it also allows for the integration of additional functions by moulding facilities for them directly into modules. Coolant paths are prime candidates for this, the automotive powertrain specialist says.

The fluids expert stresses the importance of co-engineering when addressing the designs and materials for direct thermal management of battery systems containing structural polymeric material. “For immersive thermal management systems, the materials and functional tests should be carried out very early on in the design pathway to ensure compatibility with the fluid and to maintain system safety,” he says.

If not specifically engineered for thermal conductivity, the first materials specialist says, polymer cases will need smart heat path solutions to achieve the required heat transfer rates. “The design key is to make sure the system – no matter where the hotspots are – has a way to transport heat, which with thermal isolators such as plastics is a challenge,” he says.

The fluids specialist recently launched a new dielectric coolant for directly cooling batteries, power electronics and motors as part of a range of fluids for EVs that also includes e-transmission fluids and e-greases.

This thermal management fluid has a lower viscosity than conventional dielectric coolants such as transformer fluids, the company says. The fluid is also a strong electrical insulator, has a high flash point and resists oxidation, helping to maintain its performance over time.

Independent tests show that the fluid performs better than water-glycol indirect coolants and other dielectric coolants in EV lithium-ion batteries, company literature says. Compared with a water-glycol-based coolant, for example, the new fluid enabled 41% faster charging, meaning 10 minutes to 80% charge compared with 14.1 minutes for water-glycol fluids for the same type of cells.

During discharge, it has been shown to lower peak cell temperatures by 28 ºC and to reduce variation in cell temperatures by 8 ºC compared with water-glycol fluids. Compared with other dielectric fluids, it reduced peak cell temperatures by 11 ºC and variation between cells by 2 ºC.

The equivalent figures demonstrated during charging are 17C and 2C compared with water-glycol, and 11C and 3C compared with other dielectric fluids.

These improvements enabled higher performance at a given maximum temperature, the company says.

Thermal management is a key enabling technology for e-mobility, and the pace of its evolution dictates that of the whole industry to a great extent.

Acknowledgements

The author would like to thank Dr Marc Payne at Castrol BP, David Nash at Dana, Holger Schuh at Henkel, Dr Roger Busch at Mahle, Eric Dean and Dr Anurodh Tripathi at ParkerLord, Lewis Evans and Christian Marks at Senior Flexionics, and John Williams at Aspen Aerogels for their help with researching this article.

Some suppliers of thermal management equipment

Complete thermal management

systems

Dana

Mahle

Webasto

Heat exchangers and related

components

Bosch

Senior Flexonics

Thermal fluids

3M

Castrol BP

Engineered Fluids

Thermal interface materials,

adhesives, gap fillers and coatings

AkzoNobel

Aspen Aerogels

Axalta Coating Systems

Bdtronic

DuPont

Elantas

Henkel

Kerafol

Neograf

ParkerLord

Scheugenpflug

Viscotec

Voss Automotive

Wevo-Chemie

–

–

+1 450 645 1444

+49 711 501 0

+49 (89) 8 57 940

–

–

+91 80 6145 5995

+44 1495 241 500

–

+49 2131 14 2904

+44 1932 775 644

+1 281 205 0162

–

–

+31 88 969 7809

+1 508 691 1111

+44 1684 273 040

+49 7934 1040

+44 1438 734 000

+49 40 789460

+1 800 562 8483

+49 9645 88300

+1 216 529 3777

+1 877 275 5673

+49 9445 9564 0

+49 8631 92740

+49 2267 630

+49 711 167610

ONLINE PARTNERS