Analysis finds Altilium’s CAM outperforms virgin mined materials

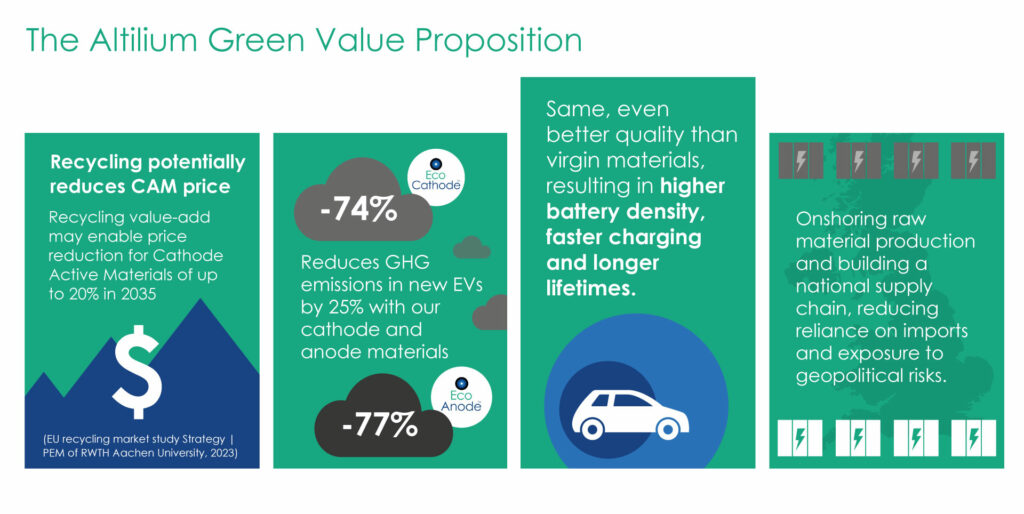

Altilium has announced the results of research by Imperial College London, revealing that its recycled cathode materials (CAM) match and outperform virgin mined materials – a critical milestone in the bid to meet net-zero targets.

Imperial College’s analysis of Altilium’s CAM confirmed improvements in purity, morphology and electrochemical performance, compared with commercially available materials. These benefits have the potential to deliver longer battery life, faster charging times and lower costs.

This involved extensive electrochemical testing of coin cells and pouch cells made with recycled CAM produced at Altilium’s ACT1 facility in Devon. With a cycle cell capacity exceeding 150 mAh.g⁻¹, the materials significantly outperformed typical ranges for mined materials.

Analysis of the recycled CAM samples also revealed significant advancements in particle size and distribution, contributing to improved stability and cycling behaviour.

Crucially, minor changes observed during testing affirmed the chemical and physical robustness of the recycled CAM.

Altilium says its proprietary EcoCathode process is capable of recovering over 95% of critical metals, including lithium, from end-of-life EV batteries.

Altilium co-founder and COO, Dr Christian Marston, said: “These results confirm the reliability and superior performance of Altilium’s materials, and validate our mission to build a UK champion for EV battery recycling. Recycled CAM not only aligns with global sustainability goals, but also offers improved technical performance at a lower cost, making it a game-changer for the EV industry.”

Unlike virgin ores, which vary in quality and require extensive refinement to remove impurities, recycled materials are derived from standardised, manufactured batteries, reducing impurities and variability in metal composition.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS