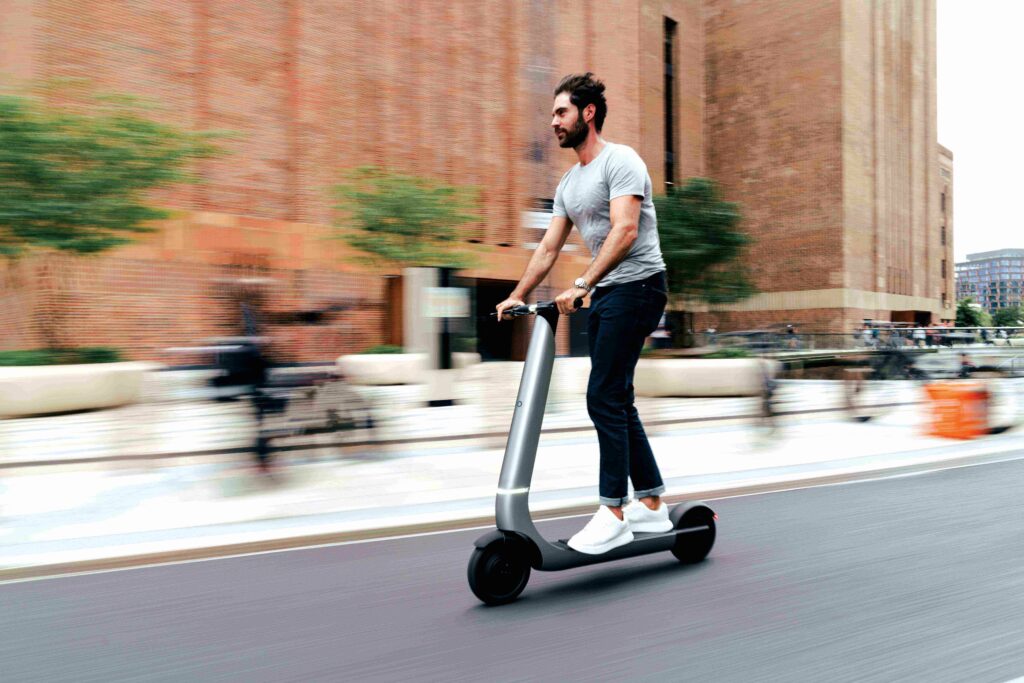

Bo M electric scooter

(Images courtesy of Bo)

Bo dazzler

A company that aims to make its e-scooter a serious, roadgoing magic carpet explains its vision to Peter Donaldson

With a side profile reminiscent of a boomerang and a sleek, unadorned, metallic finish, the ‘M’ stand-up electric scooter from Bo has a distinctive appearance that hints at a fresh approach to an increasingly popular category of minimalist, powered two-wheeler.

The project began in 2019, as a mission to bring some of the same qualities expected of cars and other ‘serious’ roadgoing vehicles to the e-scooter, according to Bo co-founder and CEO Oscar Morgan, who describes himself and his team as hardcore scooter nerds who have ridden almost everything.

“We love the e-scooter format – it’s as close as we’ve come to a magic carpet – but we found the vehicles that we purchased underwhelming and undesirable. We also felt there were a lot of marketing claims that the products failed to live up to. It seemed likely that other people felt the same way, so we imagined that if we could improve the vehicles, perhaps we could enable lots of new riders to experience the benefits of scooting,” he says.

Morgan’s co-founders, Harry Wills and Luke Robus, are the other principal members of the team behind the M scooter. Morgan and Wills met while working at Williams Formula One in the Advanced Engineering division, while Robus joined Bo from the Range Rover Future Design Studio at Jaguar Land Rover.

They wanted to build the first “mature” product in the e-scooter sector, based on the team’s collective experience in automotive engineering, meaning that refinement, aesthetics, performance and safety were prioritised.

Rewarding journeys

“In simple terms, we have worked to create a product that is truly, consistently delightful to own and live with,” Morgan says. “For us, the ideal is that you look forward to your journey as one of the best bits of your day – the most fun, least complex and genuinely rewarding way to cross your city. Failing that, the basic minimum for us is that Bo M should be like a butler – quietly intuitive and unobtrusive, so you leave your house, arrive at work, and the bit in the middle is just a happy and helpful ride.”

That is achieved across a thousand little touchpoints, including an ergonomically located lock, lights that make potholes and kerbs obvious and easy to avoid, and power delivery and braking that are intuitive. “Even the kickstand holds the vehicle upright and ready to ride, so you feel gently confident as you approach it,” he says.

The scooter is now in the initial production stage, and everything has been designed, engineered and produced in-house.

At the energy storage end of the powertrain is Bo’s own BoPower battery pack, a 48 V unit with a capacity of 672 Wh and 14 Ah. The pack is arranged in a 13S4P configuration, meaning that the battery consists of four groups of cells, with each group connected to the others in parallel, and each group containing 13 cells connected in series, totalling 52 cells.

The cells are of the cylindrical 18650 format and NMC lithium-ion chemistry that achieve high energy density while comfortably providing the required current within their operating parameters. “We have investigated the LFP currently available, which definitely holds great potential, and the options today came with a weight and peak discharge penalty,” Morgan says.

The pack casing is metallic, with glass fibre-reinforced, plastic end-caps and cell structures, and the cell-monitoring system includes temperature, voltage and current sensing, which operates during both charging and discharging.

On a full charge, the quoted maximum range is 50 km in the more economical ‘comfort’ mode and 30 km in ‘performance’ mode, where the top speeds are 25 kph and 35 kph, respectively. Performance mode also makes maximum torque available.

The scooter comes with an external fast charger that takes three hours to bring the pack up to 80% and four hours to achieve a full charge. This charger connects directly to the battery and is managed by the BMS.

“Some scooters are starting to use OBCs [onboard chargers] and that has one great advantage – you don’t have to carry the ‘charge brick’, you only have to carry a cable. We love that. However, the weight and packaging are a challenge,” says Morgan.

Safety mechanisms

With e-scooters in the spotlight for battery fires, developers need a systematic approach to maximising safety. Morgan says: “We use high-quality cells in a tough housing extruded from 6061 aluminium alloy, with a high-quality BMS and high-quality intelligent charger, which work with each other to maintain cautious operational parameters for temperature and voltage.

“So long as a high-quality cell stays within its correct voltage and temperature window, it ought to always be safe, so we focus on ensuring that’s the case.”

Sensing the abovementioned key parameters is supported by data-logging that records all battery cycles and health parameters, which is important for servicing and warranty support.

The scooter is powered by a single BoPower motor, integrated into the rear wheel hub, which is controlled by a sine wave electronic speed controller (ESC). This is a bespoke, three-phase AC machine, rated at 400 W continuous power, which can develop up to 1,200 W of peak power for short periods.

Morgan emphasises that this is a real-world number, rather than a theoretical one, based on nominal figures for voltage and amperage multiplied together. Rotor position feedback for control is provided by Hall sensors, and the windings are of Bo’s own specification wound into a specific pattern optimised for increased efficiency by the motor factory.

That peak power is complemented by up to 38 Nm of torque that is available through a wide portion of the rev range, rather than only at maximum speed to give decent acceleration off the line and exceptional hill-climbing capability. “I’m 80 kg when riding ‘clothed’ and it will take me up a 25% incline,” says Morgan.

The motor is also set up for regenerative braking, which can recover up to 20% of the total battery charge, depending on usage.

Replenishment of the battery is carried out with a 3.0 A ‘intelligent’ charger that includes a comms line through which it performs an electronic handshake with the battery management system (BMS) to confirm it is safe to charge and control the process.

Morgan says his favourite aspect of the charging system is the orange, armoured cable. He explains: “We made it slightly longer than the industry standard, and took care in our charge-port selection to ensure the experience of the cable orientation and charge plug-in is positive for our riders.

“These seem like small details, but they come from years of scooter riding and hundreds of interactions, which we now use to inform our design decisions to give people the best experience possible.”

Controls and parameters

Onboard communication for control of the scooter’s subsystem uses universal asynchronous receiver-transmitter (UART) technology for primary functions such as on/off, mode shift, power requests and regenerative braking control, vehicle health monitoring and protection, and also for ancillary functions, including lighting and secondary power-out to run accessories.

The Bo M scooter’s brain is the ECU that controls key parameters, and manages fault detection and safety functions. With both hardware and software enveloped in partnership with their powertrain manufacturer, the ECU controls power drawn from the battery in response to the rider’s use of the thumb-lever throttle on the right bar, and manages the regenerative braking. In response to mode selections by the rider, it changes the motor’s power-delivery characteristics. The ECU also controls the lights.

The lighting system includes an 800 lumen headlight with automatic temperature-controlled brightness, so it will dim to 500 lumens or less when parked to keep the LED healthy and maximise life. There is also a 200 lumen rear light, and a 500 lumen daytime running light (DRL) that creates a 270° arc of light around the rider to improve their conspicuity.

Power for the lights comes from a DC-DC converter feeding a 12 V rail.

In handling torque and speed control of the motor, the ECU ‘triangulates’ to give an output that is a combination of torque request, based on load, and speed request based on throttle position.

“This allows for both steady-state riding at part-throttle with appropriate torque input for accelerations. The aim is high performance on tap with excellent modularity for new riders and plenty of fun for experienced riders,” Morgan says.

The two riding modes are enabled by the ECU and changed by the rider with a double press of the scooter’s on/off button. The accelerator mapping behind these simple choices was arrived at through exhaustive iterative testing, Morgan says, with the aim of providing a significant difference between them, according to the rider’s desire to maximise either range or power, and fun.

“We tried various products where there did not seem to be a meaningful difference between the power modes. We did not want the modes simply to tick a box. In economy, the current draw genuinely changes and increases the Bo’s range,” Morgan explains.

Damage limitation

He says the ECU registers and reads out any faults that may occur, but does not currently have any predictive maintenance functions. “Having done our own investigation to the various claimed intelligent/AI predictive maintenance systems in this sector, our conclusion is that a lot of buzzwords are being used to describe normal and not particularly intelligent systems.”

However, the ECU does take steps to mitigate conditions that could lead to damage, most of which are temperature related. “The ECU will derate the battery when it starts to approach over-temperature and works with the BMS to ensure similar safety when charging,” he says.

On the rider safety front, the ECU is programmed to reduce power in conditions that are outside the normal operating window, and the electrical system as a whole has some redundancy to cope with ECU failure. For example, the BMS will act as wingman for any operational issues affecting the battery, while the default for the motor is to cut power so that an uncontrolled, wide-open throttle condition is not possible, Morgan says.

“Our focus is primarily on ensuring that so long as a given fault reading does not present an actual danger to the vehicle or rider, the vehicle does everything possible to keep riding, even in the presence of a minor fault. The logic here is that if a component is developing an issue, we are likely to end up replacing it either way, so what matters is that the vehicle gets you safely home or to a service centre,” he adds.

The ECU supports over-the-air (OTA) firmware, updated using the Bluetooth low-energy (BTLE) standard. As with the rest of the electrical system, the Bo M’s ECU has an IP66 ingress protection rating, indicating that it was built to keep liquid water and humidity out.

Morgan argues that there are two philosophies with water-proofing: “Either you prevent water ever getting in and therefore the components do not have to be so waterproof, or you assume water will always find a way eventually and therefore protect each component and connection individually – the latter is the approach we have taken.”

The ECU has been through vibration and shock testing in both the lab and the real world. To cool the unit, thermal paste conducts heat to the housing and provides a degree of mechanical protection. “Importantly, we strongly recommend people never fit Bo (or any scooter) with solid tyres – the single-fastest route to a failed motor controller,” Morgan warns.

Aluminium curves

Perhaps the most visually striking feature of the scooter is its unibody structure, which Bo calls the Monocurve. Morgan says the M is the first e-scooter in the world to use aluminium monocoque construction. The alloy is 6061 T6, which is widely used in aircraft, marine and automotive applications.

Monocurve is essentially a D-shaped, stressed skin that carries all of the static and dynamic loads in its walls. The result is a structure that is stiffer and stronger than more conventional scooter frames and, according to Morgan, offers a substantially better riding experience.

Another advantage of this structure is that it leaves substantial free internal space to house components. One of these is the tube connecting the handlebars to the front wheel. This passes through the equivalent of the front downtube, effectively separating the steerer from the chassis, and allowing bags and other cargo to be suspended in a safe and stable manner from folding hooks on the rear of the downtube without affecting the steering. Bo calls this the ‘Lock-N-Load’ system.

Morgan also considers aesthetics to be a major advantage of the Monocurve chassis. “Current e-scooters look like a collection of parts, and the Bo Monocurve is unique in packaging all this into a single, homogenous unit,” he says.

The aluminium monocoque structure also brings some disadvantages, he admits, including difficulty of manufacture, a possible propensity to pick up dents and scratches if the rider is not careful, and to some extent weight. “In its current format it trades portability for toughness and ride quality.”

Scooters in general are not the most stable of powered two-wheelers, so Bo wanted to improve that without sacrificing the manoeuvrability and agility that make scooters such attractive urban transport. The Monocurve structure is very stiff, providing a good foundation for optimising the combination of wheelbase, wheel and tyre dimensions, steering head angle, handlebar width and steering-stem length to get the handling balance they wanted.

Tyres and steering

Playing a key part in this is Bo’s patented Safesteer system, which allowed them to raise the ground clearance and deck height slightly above the dynamic ideal to give more battery space and ‘off-kerb’ ability, Morgan says.

Safesteer is designed to stabilise steering, particularly when running on the kinds of bumpy roads and uneven ground that disturbs most small-wheeled vehicles. At the heart of the system is a tuned pair of opposing torsion springs, on which the company spent a lot of engineering and testing effort to optimise the ramping profile, which is the way in which resistance provided by the springs increases as the steering is turned away from its neutral (straight ahead) position.

The dimensions of the wheel/tyre combination play a big part in the ride and handling, and Morgan goes as far as to say that tyre choice is the most important decision on any scooter.

“It makes a huge difference. We have gone for a brilliant CST, which combines pliancy and grip with toughness,” he says. “We’ve used 10.5 in tyres, which are slightly larger than the 8 in industry norm. However, it seems likely that all but the most compact scooters will follow suit or even go slightly larger to 11 in or 12 in.”

On the Bo M, the tyres are also effectively the suspension, and their balance between stiffness and compliance is therefore crucial to both handling and ride quality. With this in mind, the team put a lot of effort into tyre selection, trying every option on the market for dozens or hundreds of kilometres each over a period of four years, Morgan recalls.

“It is important to have a clear objective and to chart each option against that. For example, we see many vehicles in the sector using a particular Chao Yang tyre, which is a popular selection because it is good value and ultra-tough. However, it is not pliant and also not particularly grippy as the natural rubber content is lower, so we could not accept those trade-offs for the small percentage increase in toughness,” he says.

“We also think it’s important to have a tyre that looks nice, so worked to find a suitable balloon profile that combined the characteristics we wanted in a design that is pleasing.”

Geometry and stability

Most powered two-wheelers have mechanical suspension in the form of sprung and damped telescopic front forks and rear swing arms, but the Bo M has none. This decision was driven by the limitations of available suspension technology for this kind of vehicle.

“Suspension ruins geometry by raising the deck height, making the scooter significantly less stable and comfortable to ride. Additionally, it tends to be unreliable, heavy, noisy, requires maintenance, and at this scale of travel [<40mm] it does not work well at all,” he says. “As soon as we can solve these issues at a reasonable price-point then of course we will add it into the specification.”

In the meantime, the compliance of the tyres is sufficient. To eliminate annoying vibration, Bo fits the plate on which the rider stands with Airdeck, an engineered ethylene vinyl acetate (EVA) elastomeric foam, similar to that used in high-end training shoes. With a thickness of 11 mm, Airdeck is designed to absorb vibration in the frequency range of 10-20 Hz to prevent the discomfort of ‘pins and needles’ that can result over longer rides.

Braking is by a cable-operated drum in the front wheel in combination with the regenerative braking provided by the drive motor acting through the rear wheel. Following normal bicycle practice, the front brake is operated with a lever on the right handlebar, and the rear brake with another on the left bar.

Morgan says the team prefers the drum brake to a disc as the shoes are protected, and because most routine retardation comes from the regenerative braking it needs almost no maintenance.

Cable operation is simple and inexpensive, he says. “We’ve looked at different hydraulic and disc options, and found the hydraulic brakes don’t tend to have great modularity at this size, and the discs tend to go out of alignment and require regular pad changes. None of this is particularly well-aligned with our aim of creating a highly intuitive and low-to-zero maintenance vehicle.”

While the front brake does not have anti-lock capabilities, an e-ABS function is programmed into the regenerative braking of the rear wheel. “We have tried the bike/scooter-grade hydraulic ABS units currently available and found they offer low efficacy at a high cost,” Morgan says.

Ease of maintenance and repair was a major consideration in the design of the M and all of its components, he emphasises.

“My background is farming, where the ability to fix a machine with whatever odd tool assortment is in the box on the tractor is essential to completing tasks within short weather windows under pressure,” he continues. “I firmly believe a vehicle should be simple, fast and intuitive to service and repair as that is the number one contributor to long life.”

For example, the bolts that must be undone to remove the front wheel are different from those around them to eliminate the possibility of confusion. Every bolt on the vehicle can be turned with ordinary bicycle tools, and the rear access panels are held on with automotive clips for ease of access. Also, Bo’s online parts store is already up and running.

All design engineering and production engineering work are carried out at Bo’s headquarters near Temple Meads, Bristol, UK. Most of the components are sourced in east Asia, predominantly China, Morgan says. “They combine good value with experience, quality, speed and a wide supply network.”

Some key specifications

Length: 1204 mm

Height: 1130 mm

Width: 590 mm

Airdeck width: 146 mm

Vehicle weight: 22 kg

Tyres: 10 x 2.5 in pneumatic tyres

Max rider weight: 120 kg

Physical security: Lock-N-Load for luggage plus two forged-aluminium loop-locking points

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS